Building your own analogue sensors for the SmartBox

Friday, 29th November 2024

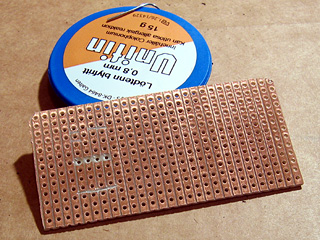

This is an extremely belated followup to a post from November last year, though one of the reasons for the delay was repeatedly being sent the wrong electronic components which ultimately led to the post from December. I'll try to explain as best I can...

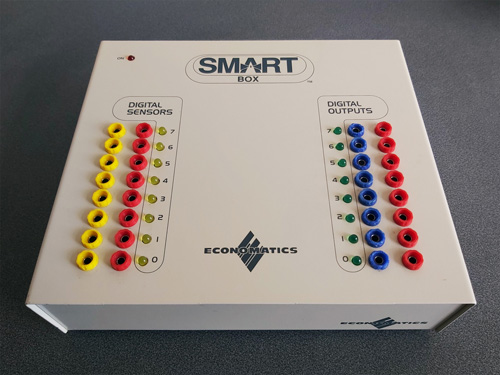

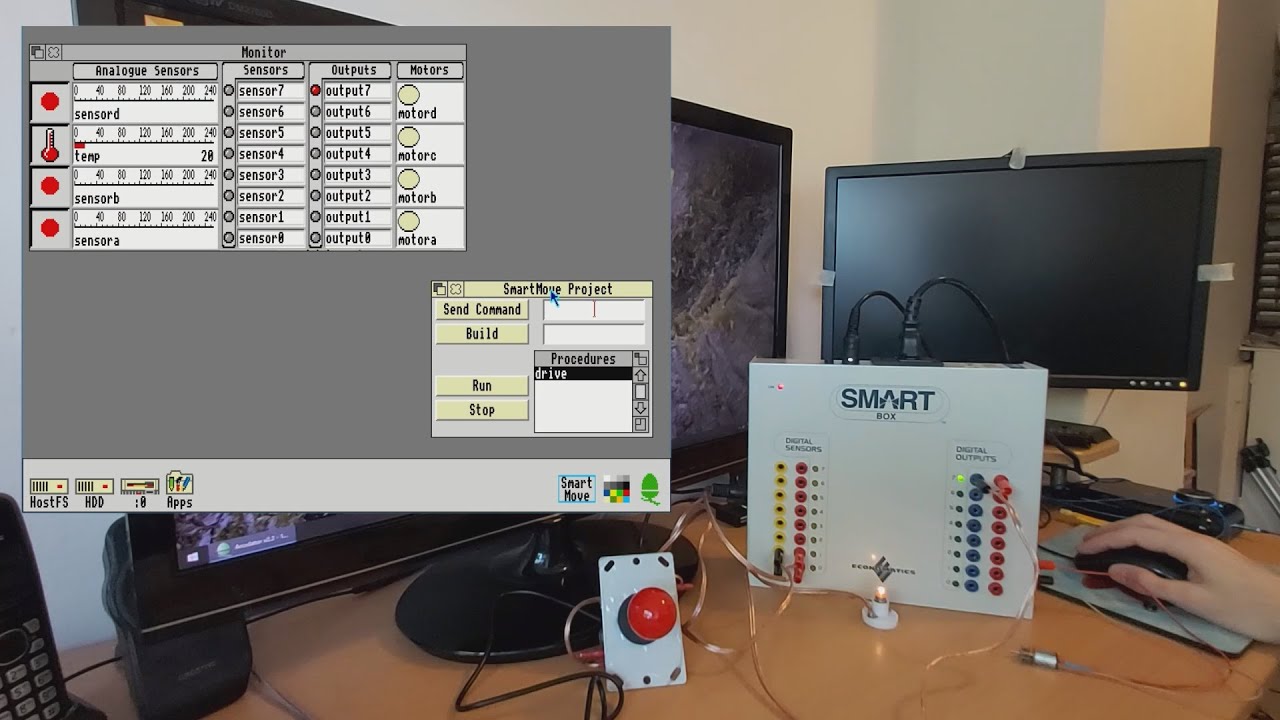

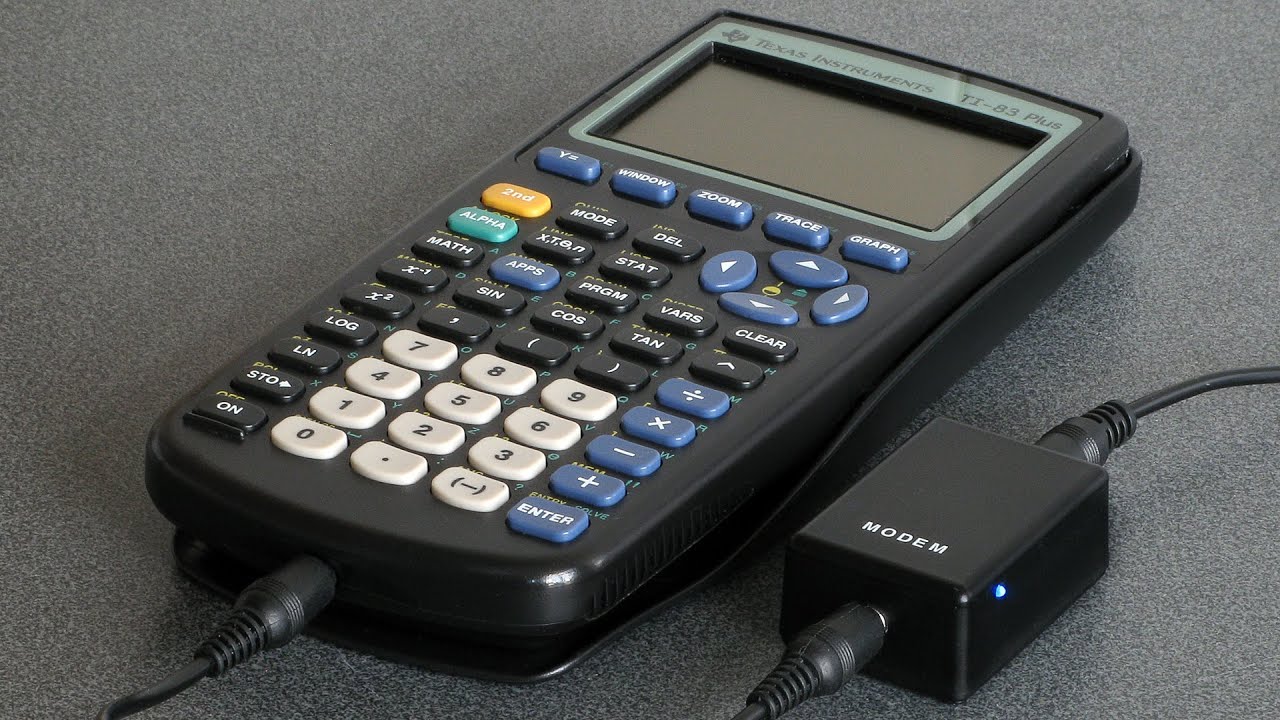

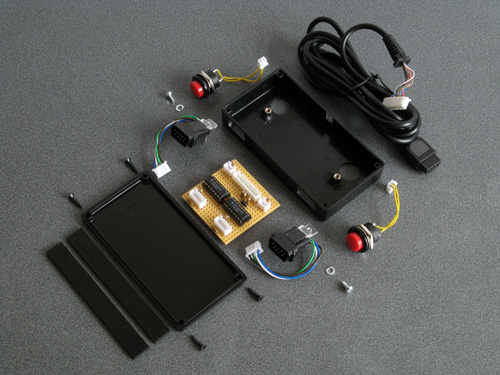

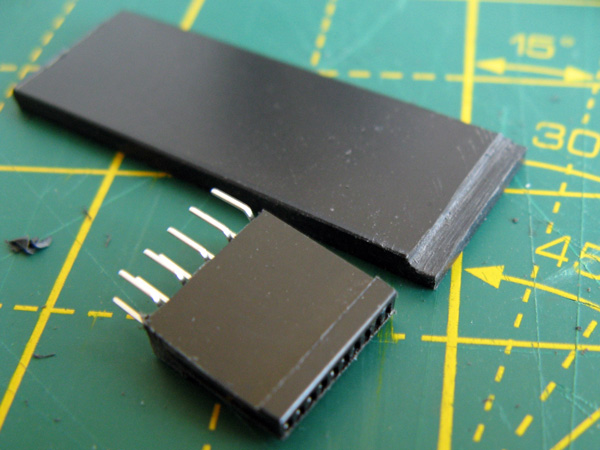

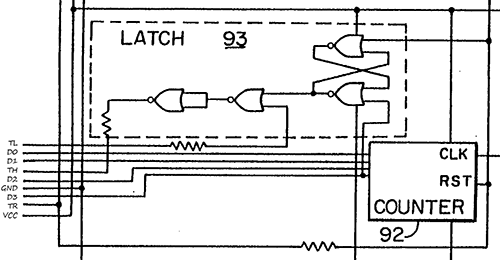

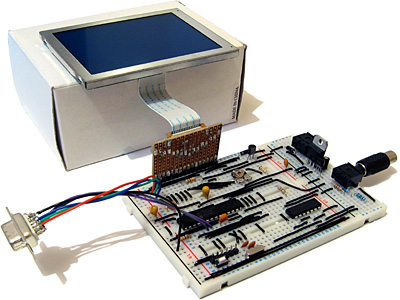

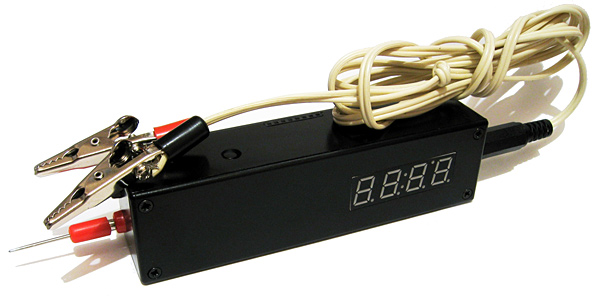

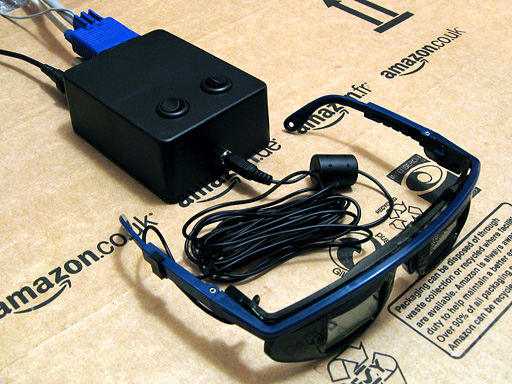

Towards the end of last year I bought myself a SmartBox, a computer control system that's based around a 65C02 CPU and that runs programs written in an interpreted BASIC-like programming language, with software uploaded via a computer's serial connection (and once the programs are loaded onto the box, the serial connection can be severed and the program will continue to run). In the previous journal entry I focussed more on the software side, though to get practical use out of the box I had experimented with some of the hardware too and had built some analogue sensors that I was hoping to write up for the benefit of anyone else who'd acquired a SmartBox but none of the sensors to go with it.

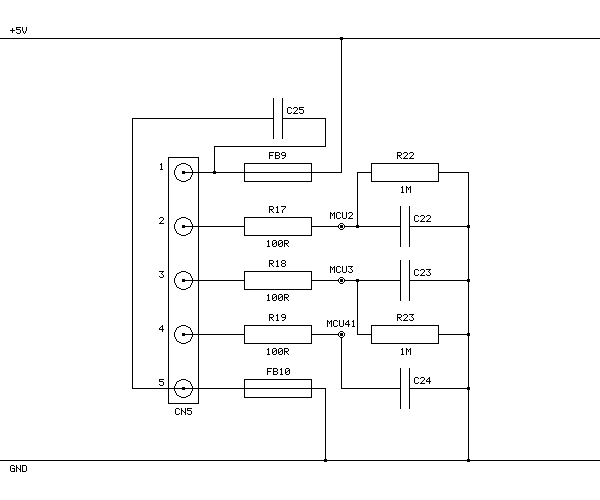

The four analogue sensor ports on the side of the SmartBox use 5-pin DIN sockets (180° to differentiate them from the 240° 5-pin DIN socket used for the serial port). Each sensor port can measure an analogue value with an 8-bit resolution (between 0 and 255) with the maximum voltage refererence being set to 2.55V – that is, each unit in the 0–255 range reported by the sensor corresponds to 1/100V (10mV), so if you connected a 1.5V source to the sensor port you'd see a value of 150 returned.

Sensors were made that measured specific physical properties (such as light level, humidity, temperature, or sound level) as well as generic "User Adaptor" boxes that allowed users to connect their own sensors:

The SmartBox "User Adaptor" pictured in a brochure.

One other nice trick that the analogue sensors had was that they could report which type of sensor they were directly to the SmartBox, so when you plugged in a temperature probe (for example) it would know that it was measuring temperature on that sensor port. The way this was implemented is via a "sense signal" output pin from the SmartBox to the sensor. In normal operation it was low, and the voltage read on the analogue sense input pin was used as the sensor's current value. Once a second or so the SmartBox would drive this pin high, and the voltage read on the analogue sense input pin was used to determine the type of sensor.

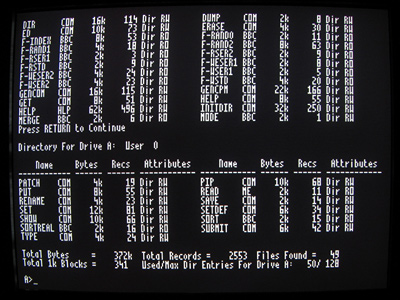

There are 32 possible sensor IDs. The ADC reading mentioned in the table below is the minimum value that will cause the Smart Move software to identify a particular sensor, for example a humidity sensor can be identified with an ADC reading between 157 and 164:

| ADC | Smart Move 1.16 | Smart Move 1.18 |

|---|---|---|

| 0 | No sensor | No sensor |

| 5 | mT | |

| 13 | mm | Temp |

| 21 | No sensor | No sensor |

| 29 | No sensor | No sensor |

| 37 | Temp | Volts |

| 45 | Temp | Temp |

| 53 | mA | Volts |

| 61 | Sound | Temp |

| 69 | Sound | Sound |

| 77 | Sound | PH |

| 85 | Pulse | |

| 93 | Position | Position |

| 101 | ||

| 109 | ||

| 117 | ||

| 125 | Light | Light |

| 133 | ||

| 141 | ||

| 149 | ||

| 157 | Humidity | Humidity |

| 165 | Sound | |

| 173 | Light | |

| 181 | Pressure | Sound |

| 189 | ||

| 197 | PH | Atmos |

| 205 | Light | |

| 213 | User | |

| 221 | Adaptor | Adaptor |

| 229 | Lux | Temp |

| 237 | Volts | LGate |

| 245 | Wind | |

| 253 | Temp | Temp |

Note that Smart Move 1.16 and Smart Move 1.18 have some different names for some sensors. If a space is left blank in the table then the sensor is treated as present but is labelled "SENSORA" to "SENSORD" instead of being renamed according to the sensor type.

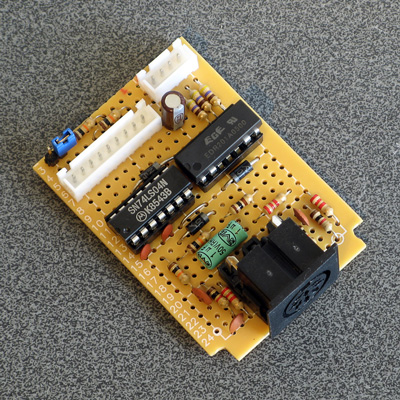

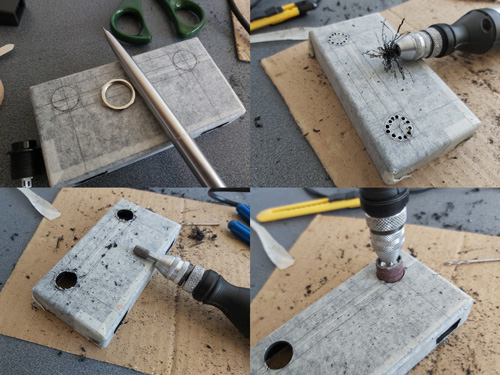

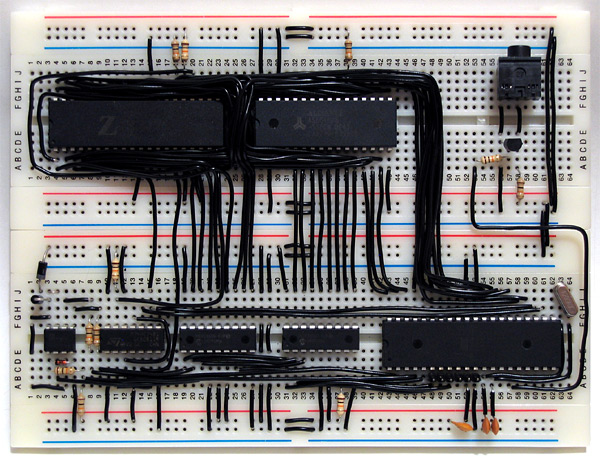

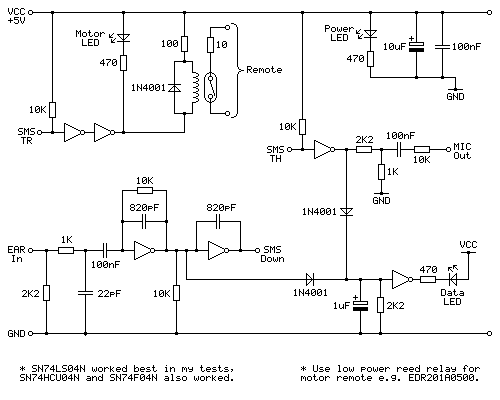

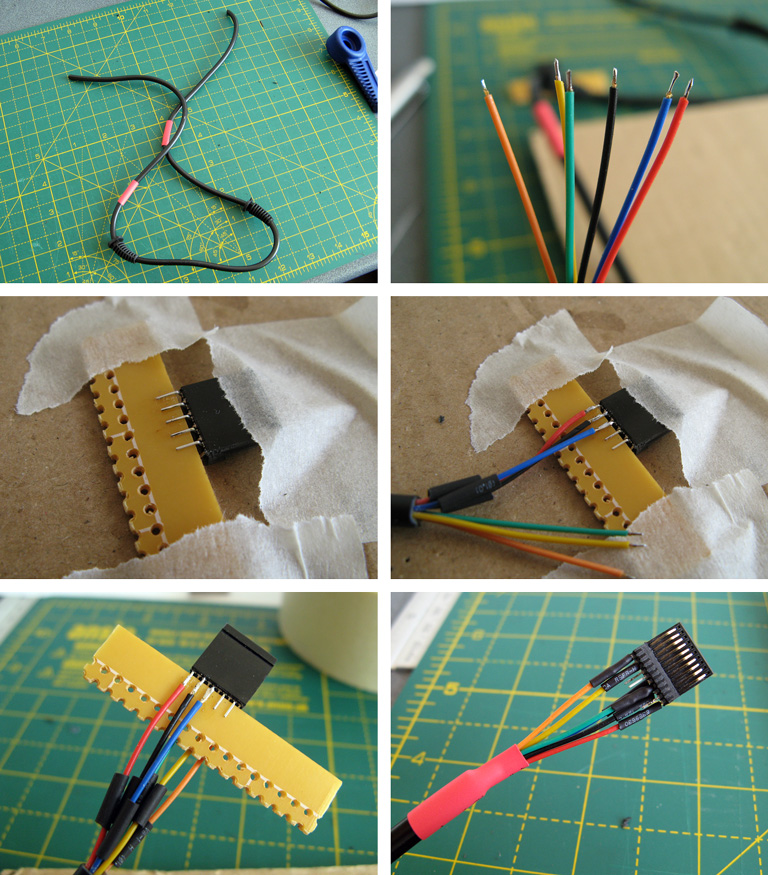

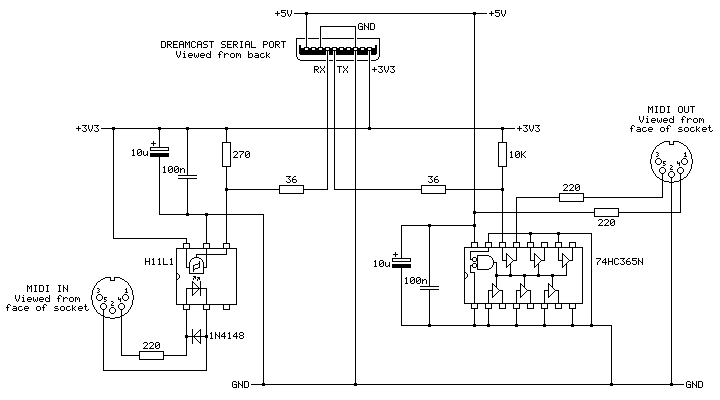

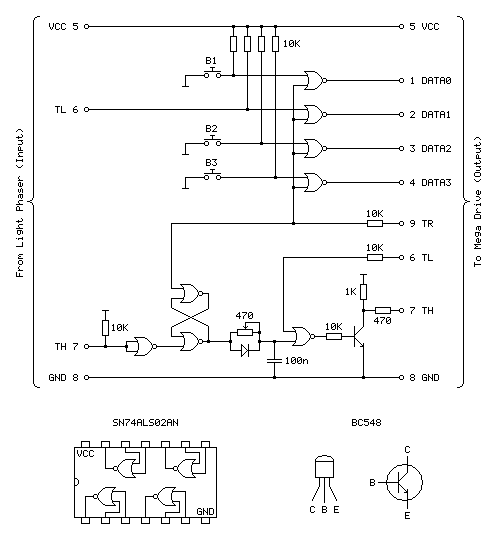

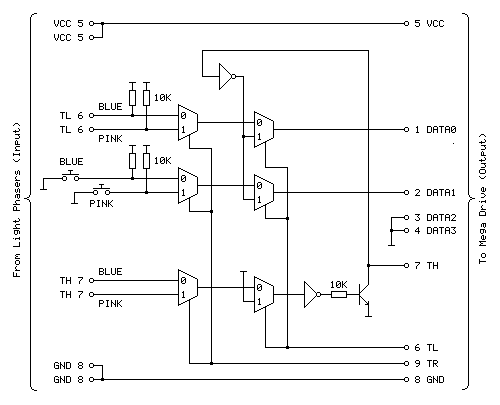

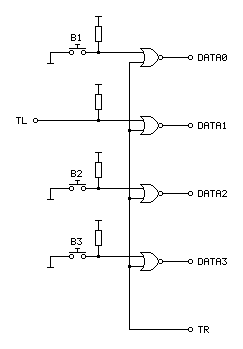

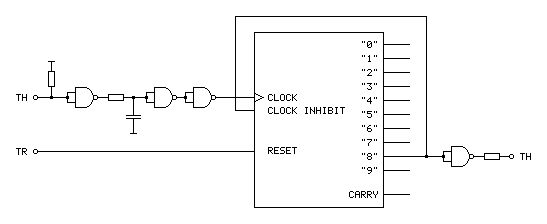

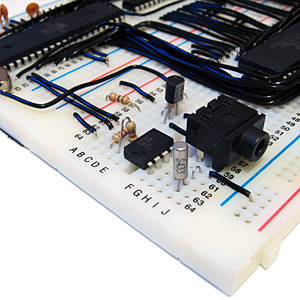

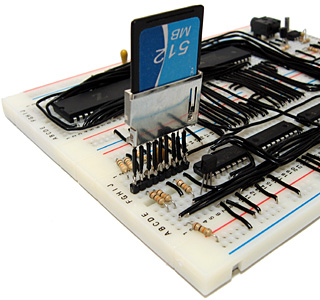

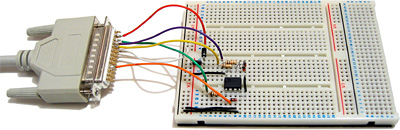

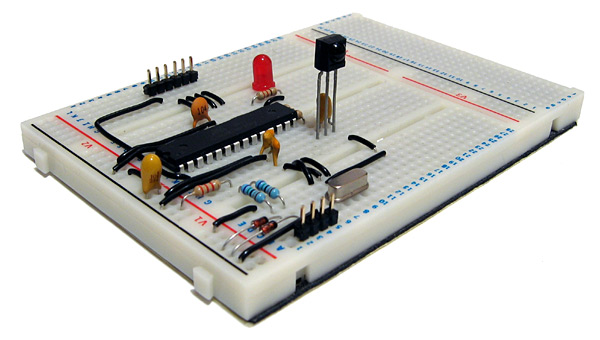

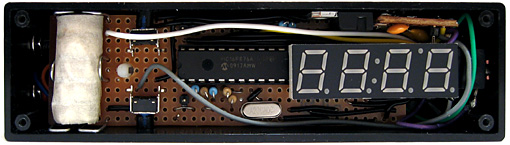

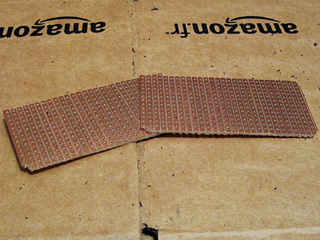

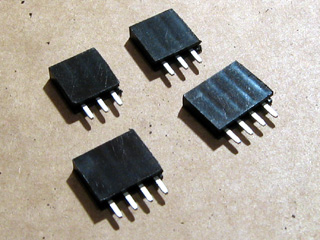

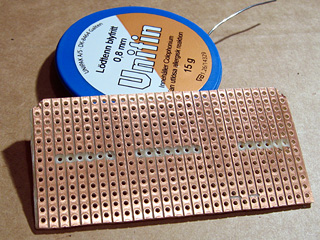

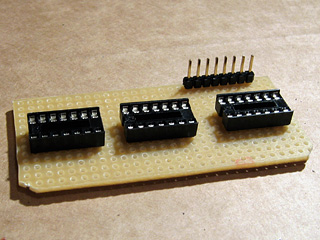

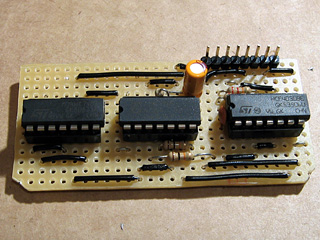

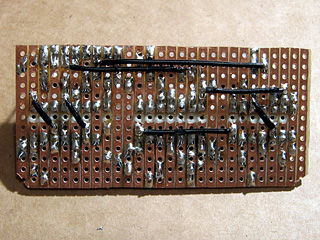

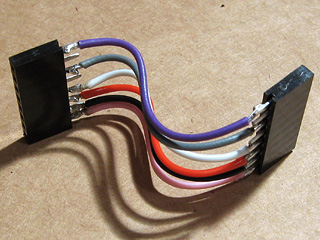

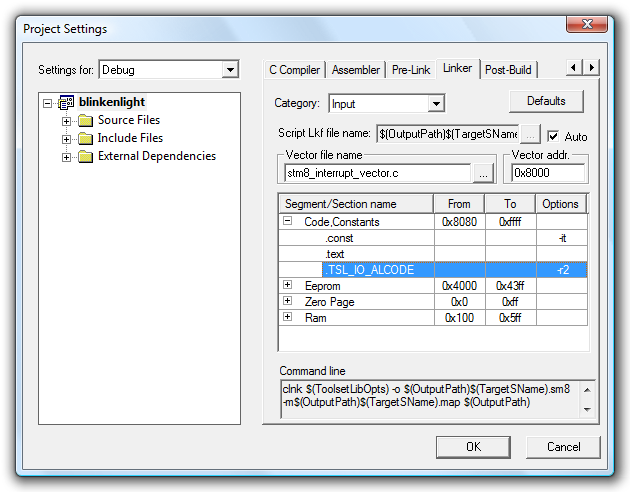

An analogue multiplexer (such as a 4053 IC) can be used as the basis for an analogue sensor for the SmartBox, sending either the voltage to measure or a reference voltage set with a preset potentiometer to identify the sensor type. The "sense signal" output from the SmartBox chooses which of the two voltages to return:

When the adaptor is connected to the SmartBox the potentiometer RV1 can be adjusted to choose the sensor type. As this is only checked once per second it can be a little fiddly to dial in the specific value you want — temporarily bridging A0 and A1 on the 4053 (so that RV1 is used as both sensor type and input value) and watching the reported sensor value can make life easier (making sure any sensor is disconnected from the input socket, of course).

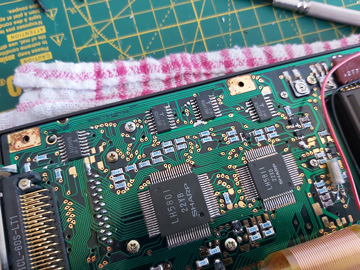

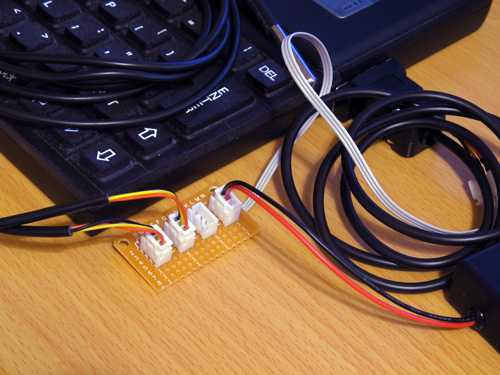

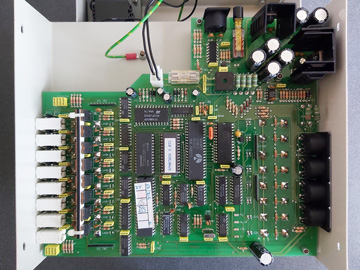

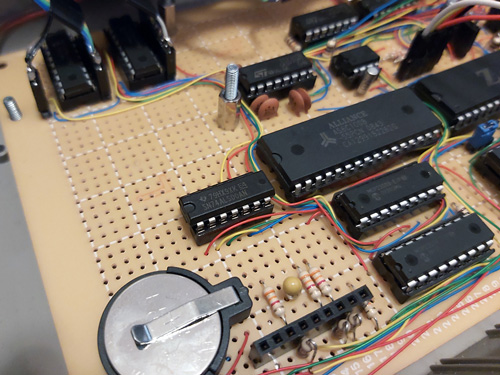

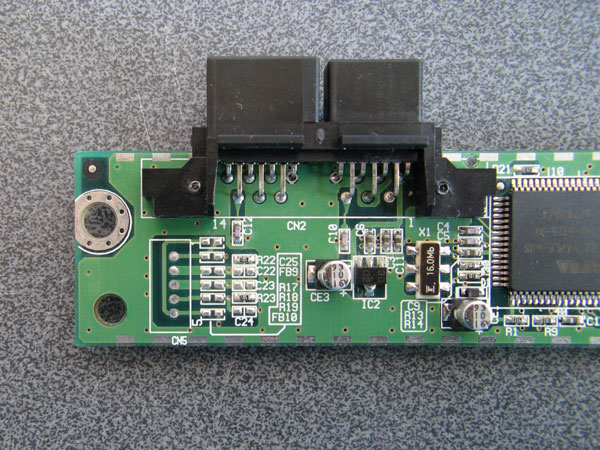

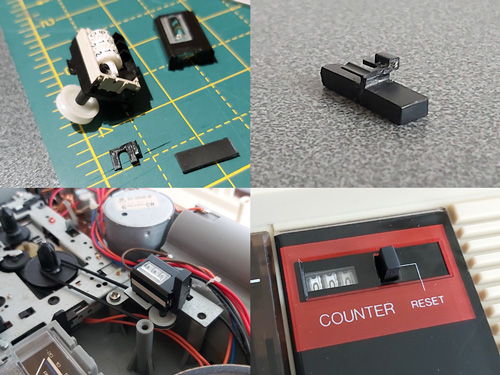

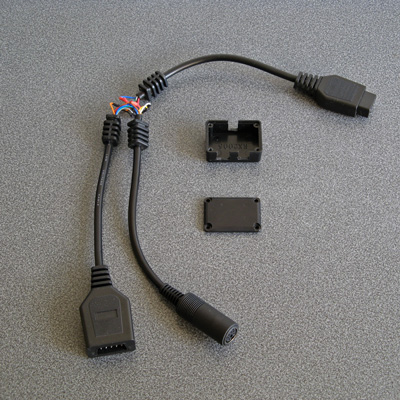

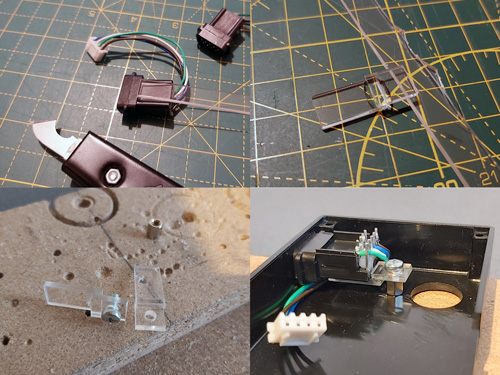

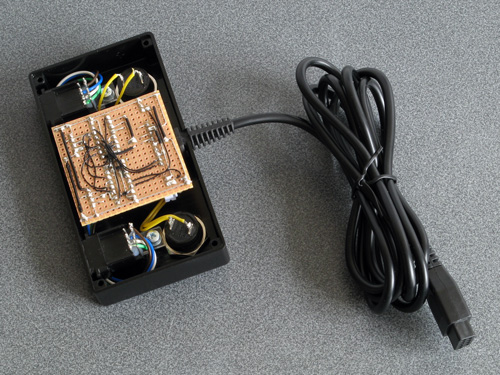

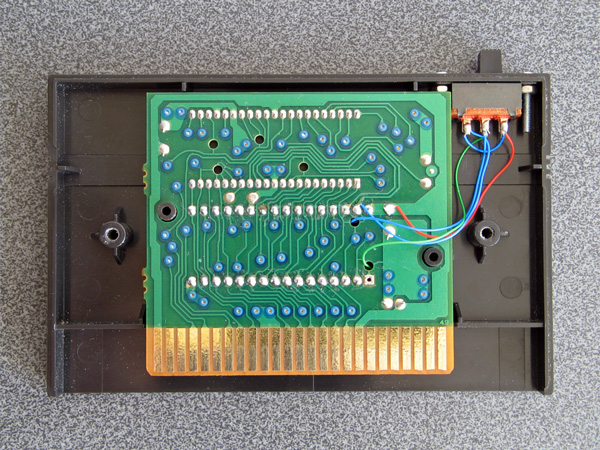

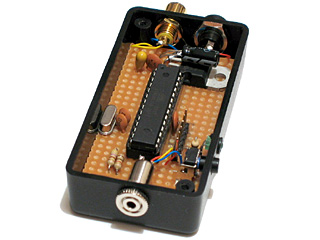

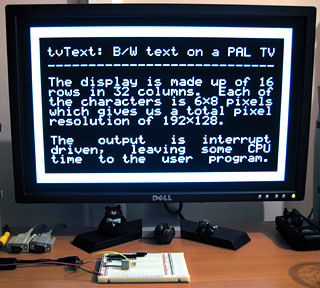

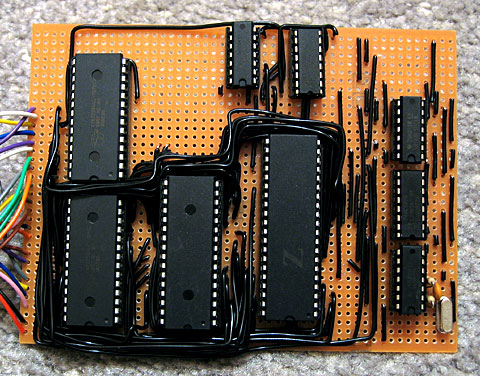

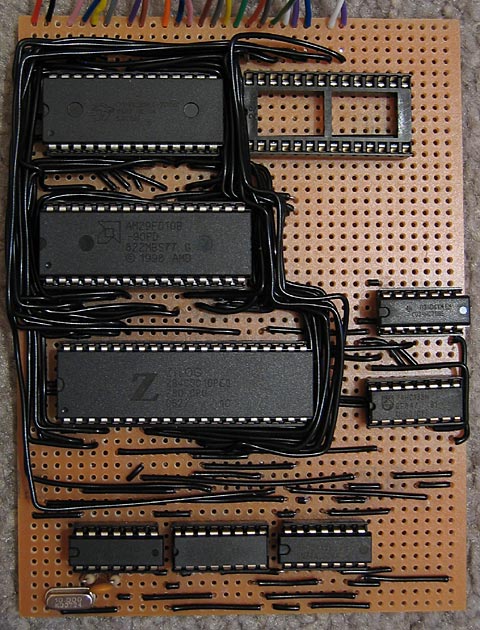

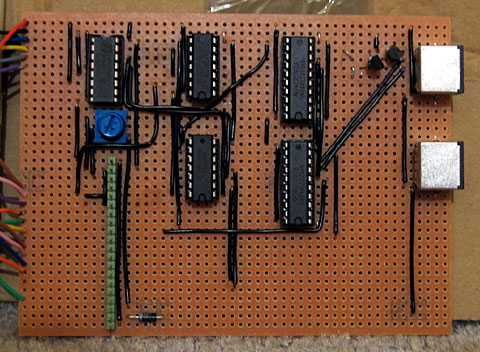

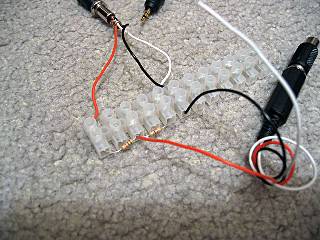

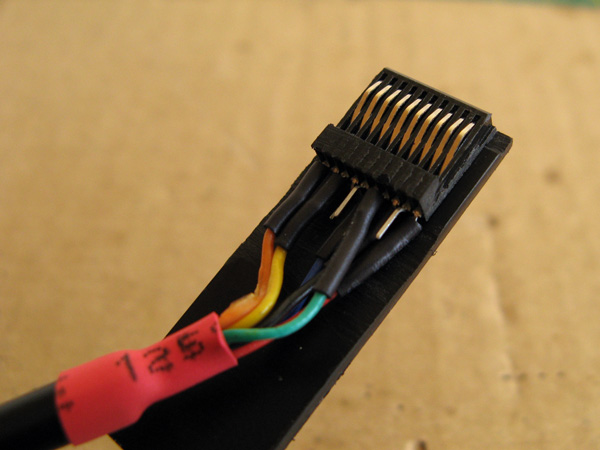

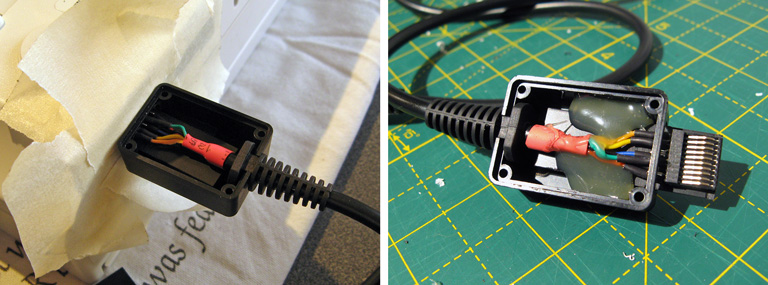

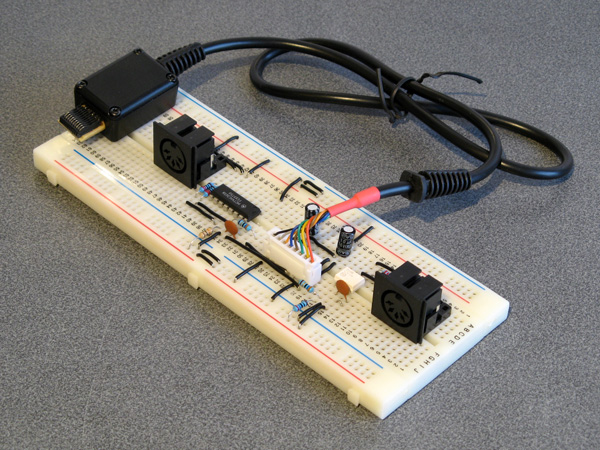

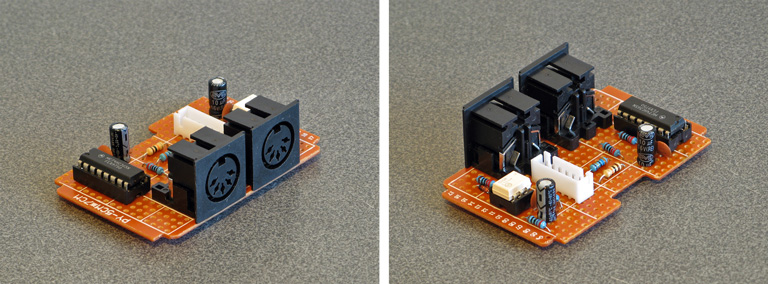

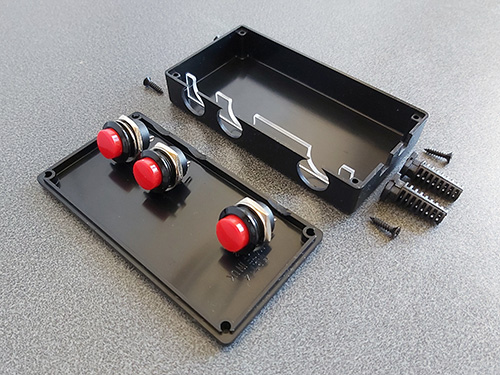

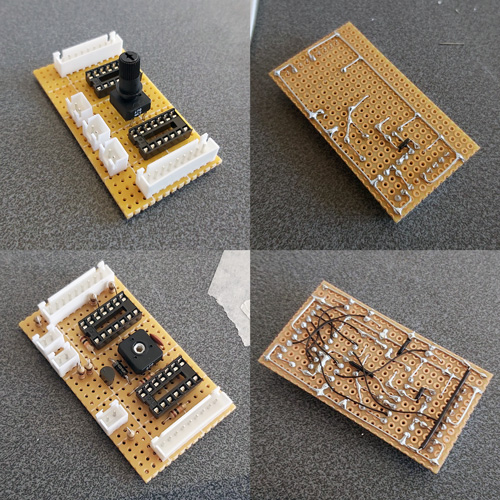

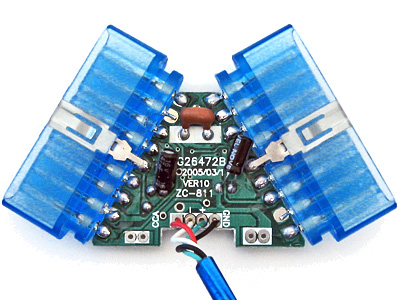

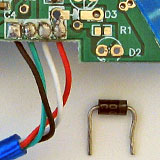

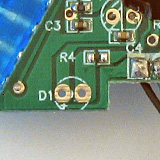

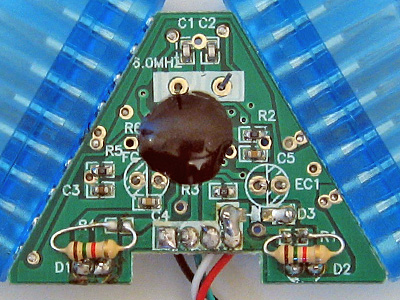

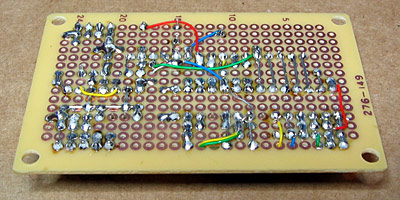

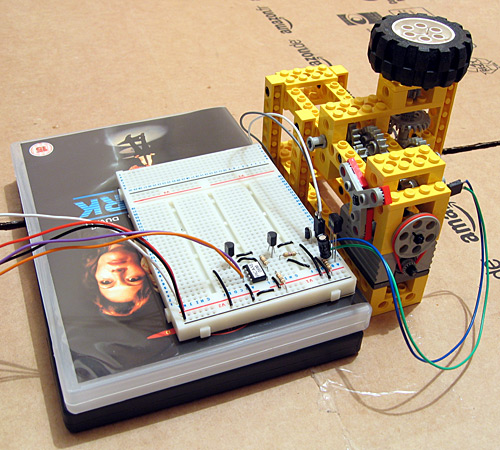

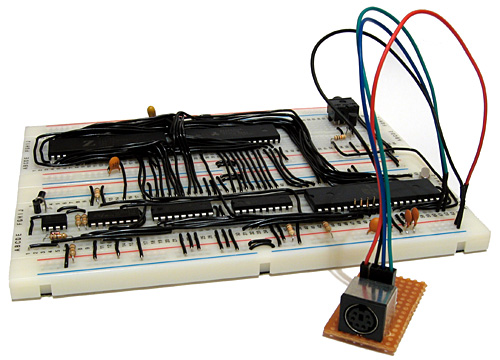

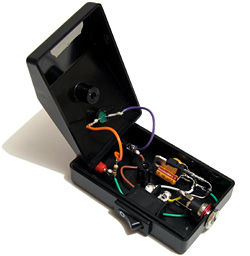

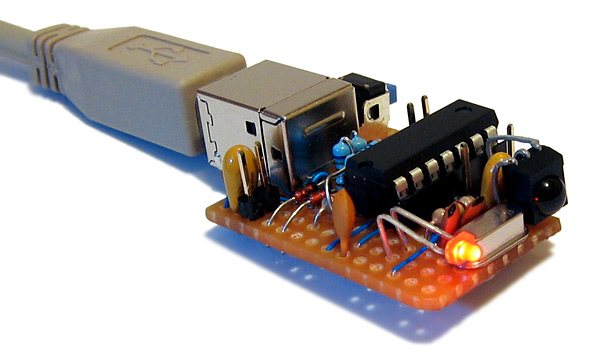

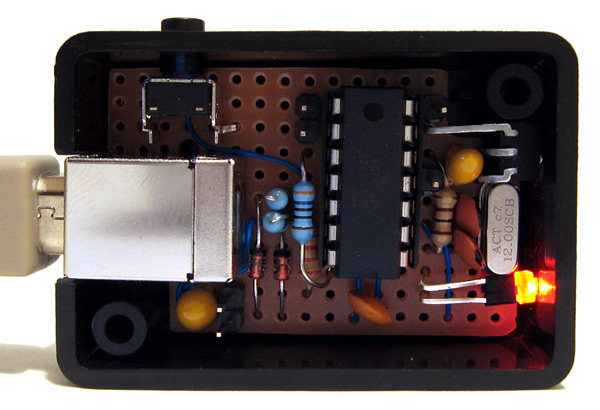

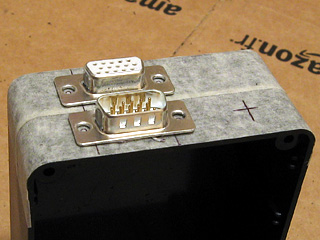

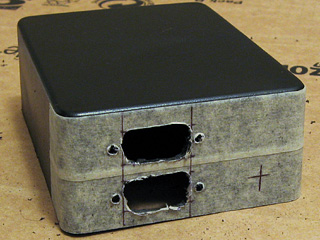

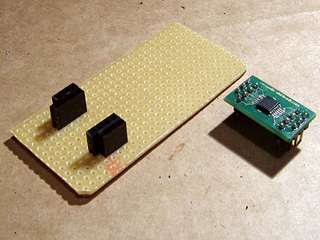

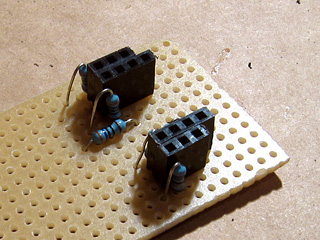

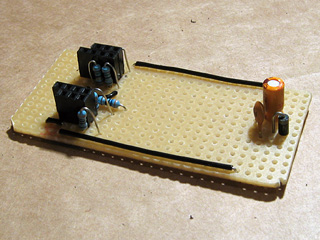

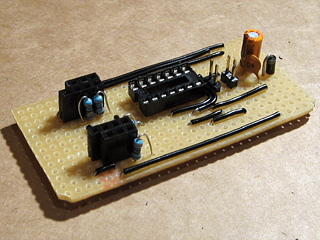

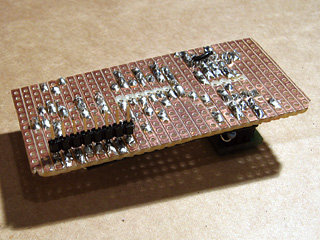

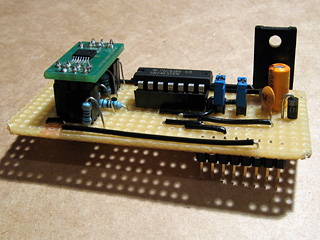

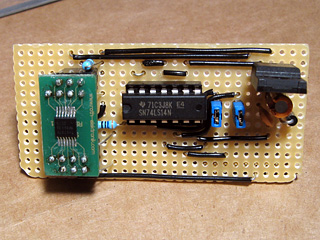

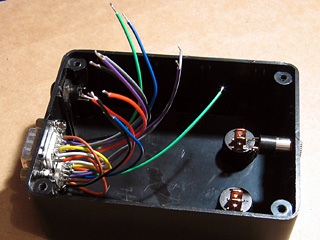

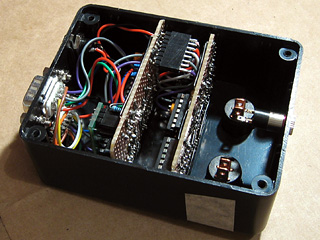

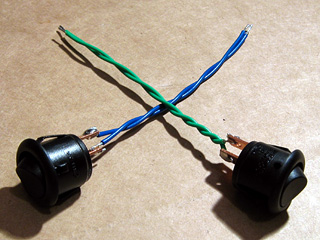

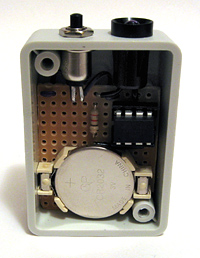

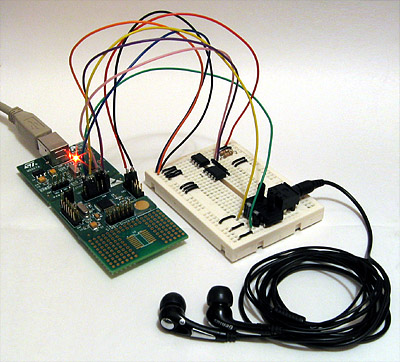

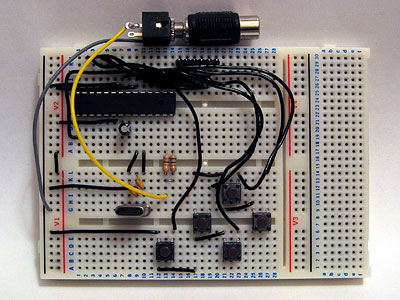

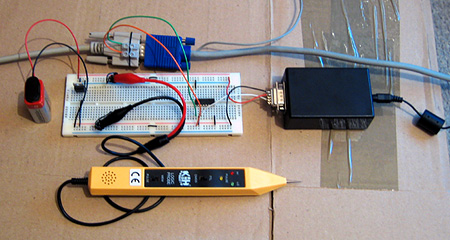

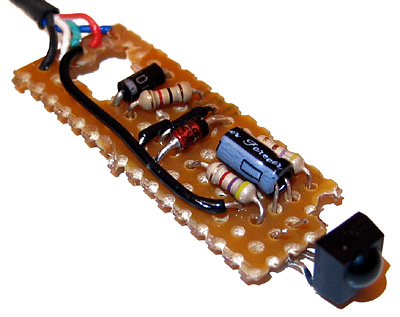

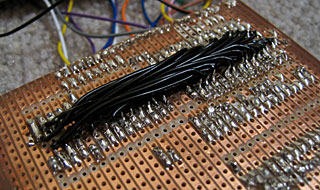

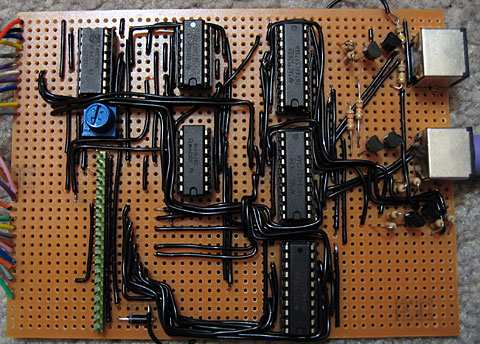

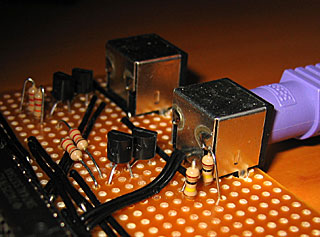

The internal components of the home-made User Adaptor.

Whilst this is a useful circuit for building custom sensors, or making a replica of the generic User Adaptor (my DIY effort pictured above) there is a simpler option that can be used for temperature sensors. The original temperature sensor doesn't seem to have very much circuitry of its own, being just a simple probe with a DIN socket on the end of a wire:

The SmartBox "Temperature Sensor" pictured in a brochure.

The temperature sensor provides a reading in Celsius directly in the software, e.g. a temperature of 25°C is reported with a value of 25. This corresponds to a 10mV/°C sensor, and an example of such a sensor is the LM35. One limitation of the LM35 is that without a negative supply voltage pulling down its output it reports a minimum temperature of 2°C, yet the brochure snippet shown above reports a range of 0°C to 100°C. However, reading the manual for the SmartBox it mentions that the Smart Sense temperature sensor measures temperatures between 2°C and 100°C which seems to further indicate that it is indeed something like the LM35.

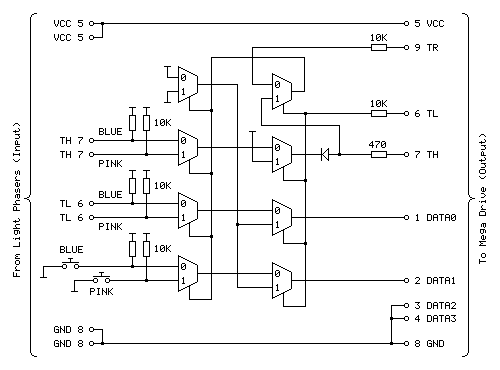

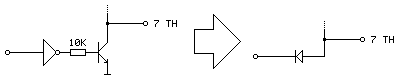

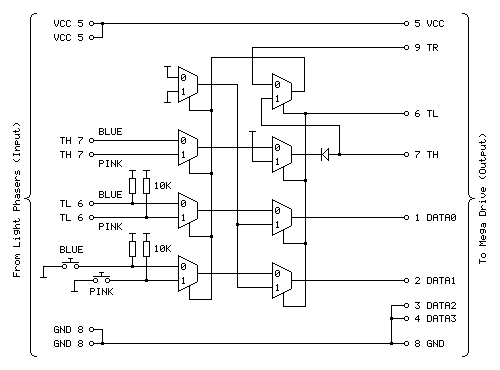

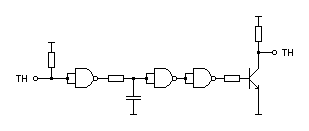

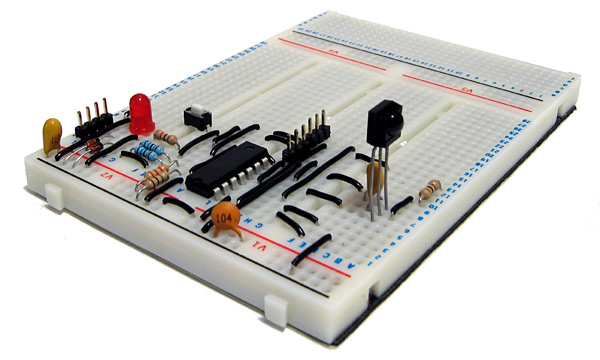

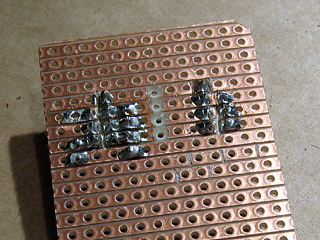

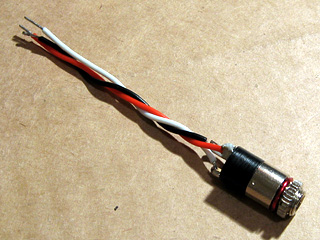

We could therefore just connect an LM35 to the User Adaptor circuit shown above and that would work, however there is a simpler circuit. If you consult the table of sensor types at the start of this post you'll notice that the temperature sensor appears at the bottom of the table with the highest sensor value. This means that to be identified as a temperature sensor, the sensor must output at least 2.53V when the "sense" pin goes high. A crude way to implement this is to connect a diode from the sense output pin back to the analogue input pin:

When the sense pin is low the voltage at "input" will be higher than the voltage at "sense" so the diode will not conduct and not influence the output of the temperature sensor. When the sense pin is high, however, the voltage at "sense" will be higher than the voltage at "input" and so the diode will conduct and raise the voltage at "input" to above 2.53V, indicating that the connected sensor is a temperature sensor.

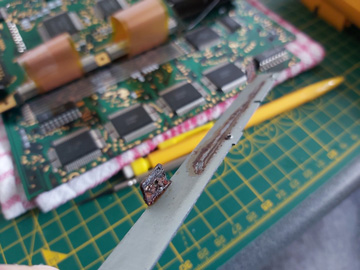

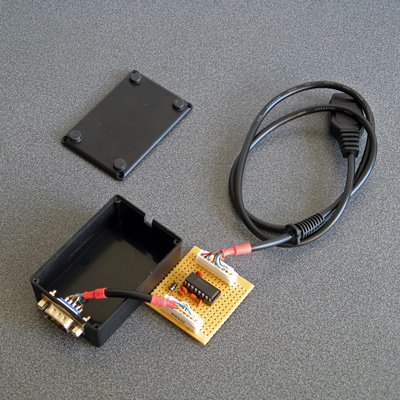

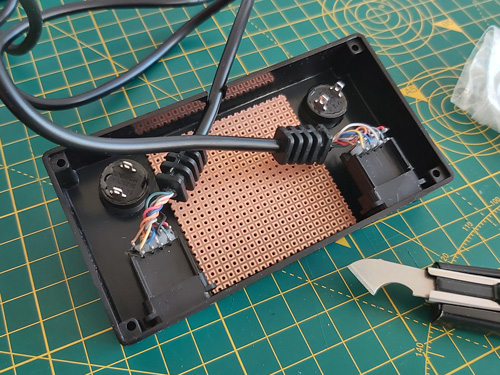

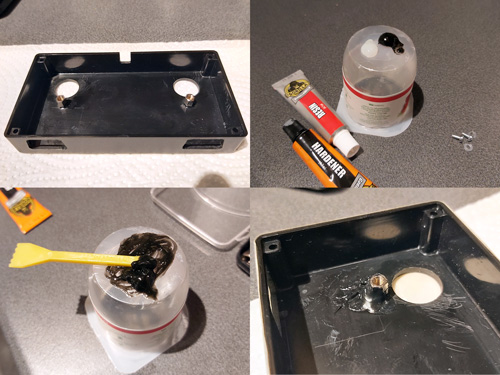

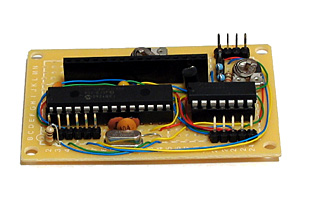

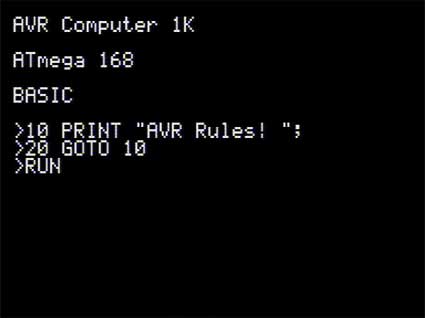

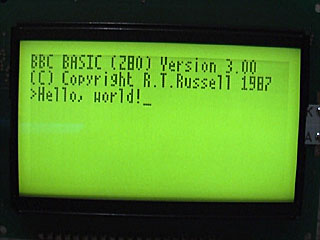

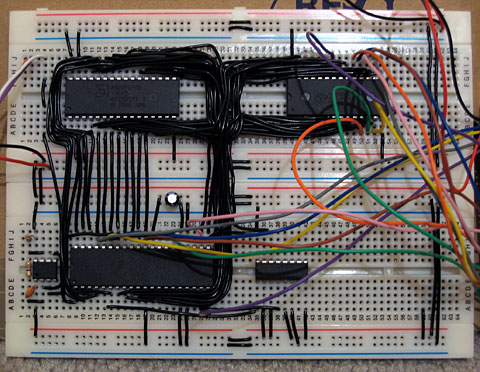

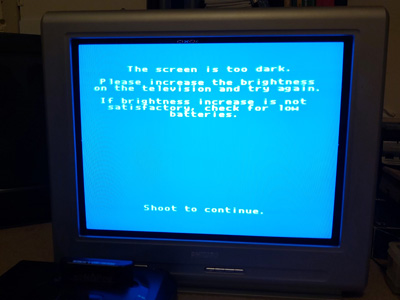

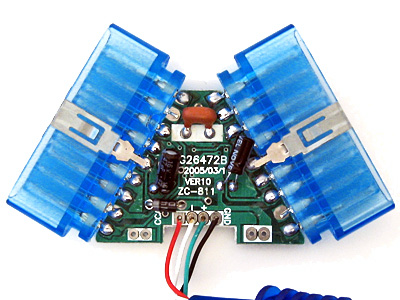

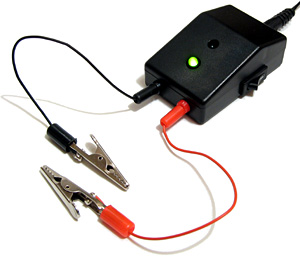

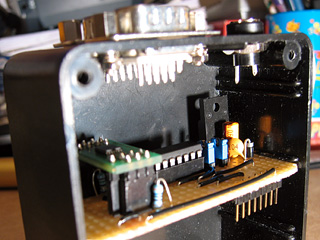

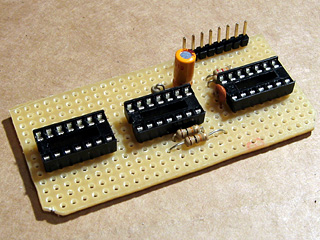

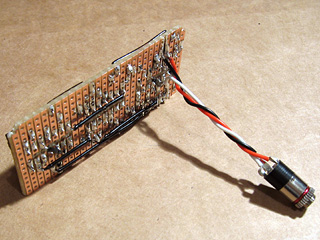

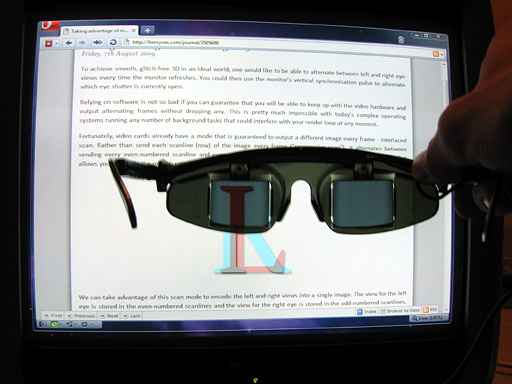

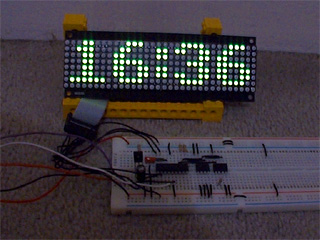

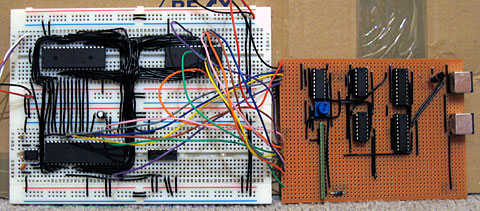

The internal components of the home-made temperature sensor.

According to the documentation for the SmartBox the inputs are protected against overvoltage so I believe this is a safe circuit to use, however as with the User Adaptor all circuits here are based on some rough guesses as to how the devices would have originally worked as I don't have any real sensors to test with myself. In any case, these sensors work for me as I've not been able to source any of the original parts, so maybe if you like me have an old SmartBox knocking around these may help you get some more use out of it.

Resampling Sharp PC-1500 tape recordings

Wednesday, 16th October 2024

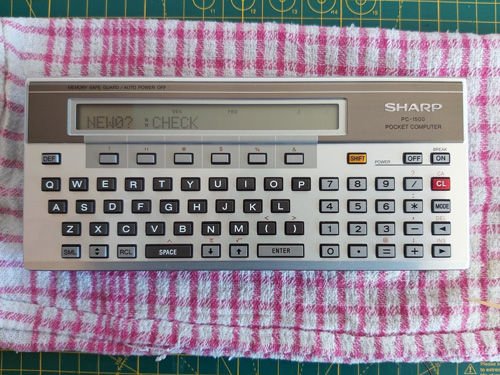

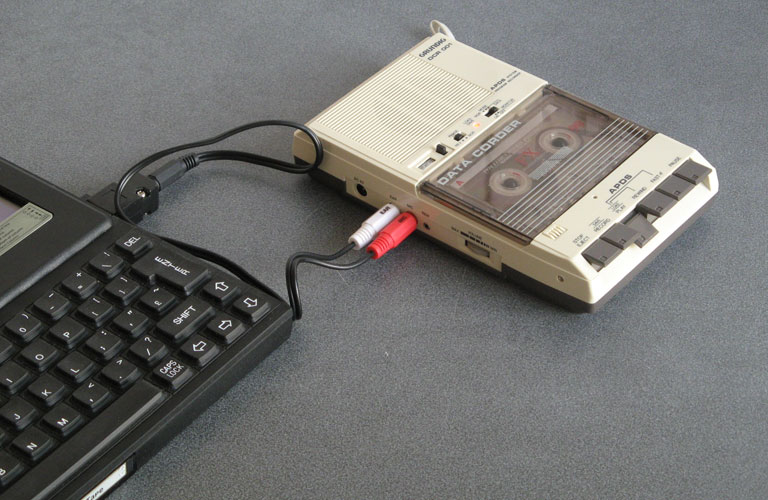

This is a quick post about problems I'd been having loading tape cassette recordings from my PC to a Sharp PC-1500 Pocket Computer along with a potential solution for anyone having similar issues.

The Sharp PC-1500 is a small computer from the early 1980s that can run programs primarily written in BASIC. Programs can be saved to and loaded back from cassette tape but to do this requires it to be connected to the CE-150, a cassette interface that also includes a four-colour plotter. It's the plotter that really attracted me to the computer in the first place, but being able to load programs from cassette rather than having to type them in by hand is definitely a very handy feature!

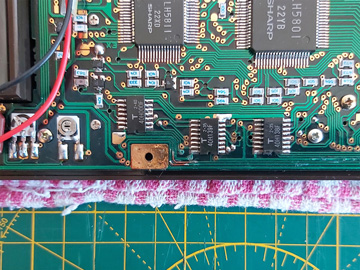

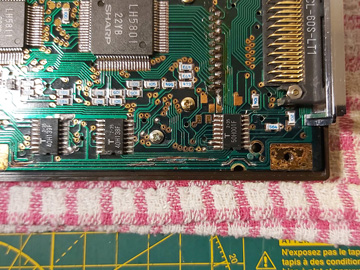

Unfortunately this CE-150 interface contains an internal battery pack of five Ni-Cd cells. A certain amount of battery leakage is a risk in any old piece of electronics hardware, but having said battery pack soldered directly in with no easy way for the user to remove it for long-term storage makes it more of a certainty than a risk. My CE-150 had not escaped, with heavy corrosion visible on the metal plate under the computer…

The inside of the PC-1500 was a bit better and not quite as musty-smelling, but circuit board traces had definitely been eaten away in places and some of the internal metal structure was looking a bit crusty.

I cleaned up the rusty metal using some appliance descaler (and recorded a video of the process, which can be found on YouTube) then got to work with a scalpel and some fine enamelled copper wire to repair the damaged traces.

Thankfully when I put it all back together again I was greeted by the NEW0? :CHECK prompt, so I connected the computer to the CE-150 and confirmed I could save and load back programs using my PC in place of a cassette recorder. Hooray!

When looking to see what other people had managed to achieve with the computer I found the Sharp PC-1500 (TRS-80 PC-2) resource page which hosts several games and applications which can be downloaded in WAV format. I downloaded a few, but when playing them back on my PC the PC-1500 would refuse to load them. It could load from my own recordings, why not these?

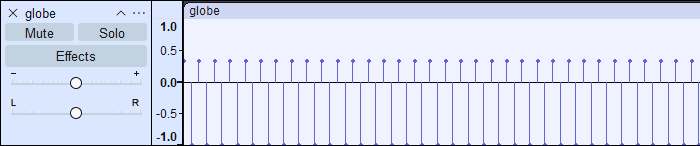

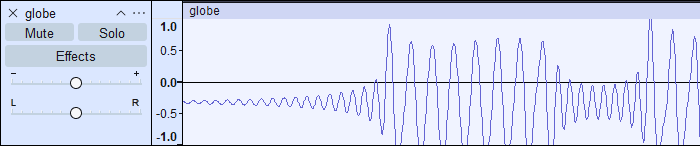

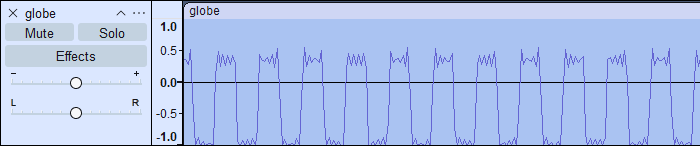

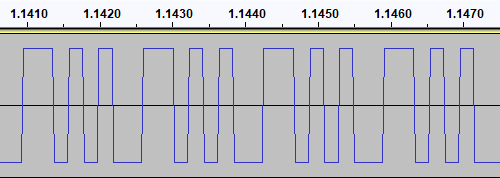

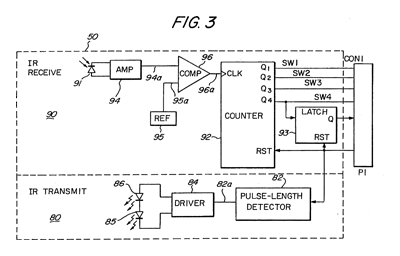

The odd thing is that my own recordings started with a few seconds of constant pilot tone followed by the varying pulses of the program data I was trying to load. When playing back the downloaded recordings they'd start with silence and only make sound when they got to the actual data – and that data sounded quite unlike what my own recordings sounded like. What was going on? I opened a recording in Audacity to see what it looked like, and zoomed in:

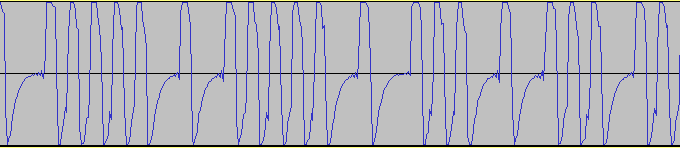

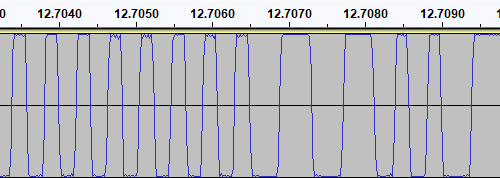

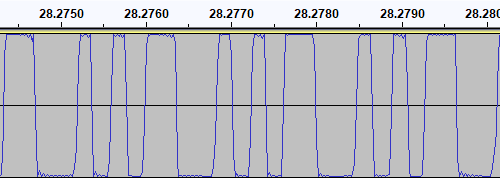

That looks like the pilot tone, in that it alternates between high and low at a fixed frequency, though it's only one sample high then one sample low so is a square wave rather than the smooth sine wave I was expecting. The cassette format uses frequency-shift keying so I would expect to see data further on in the recording at half the frequency, or twice the period, i.e. two samples high and then two samples low. Scrolling along, I certainly find that:

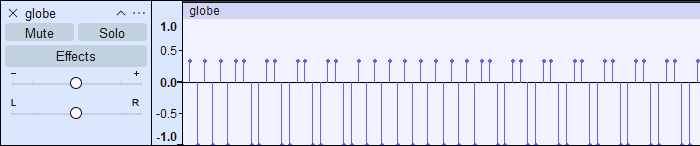

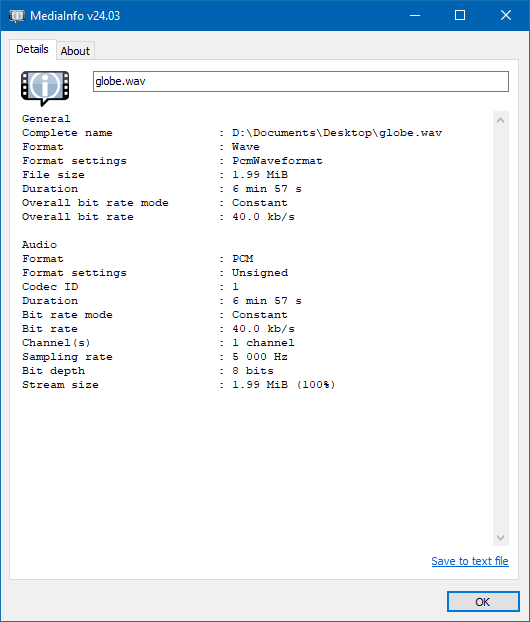

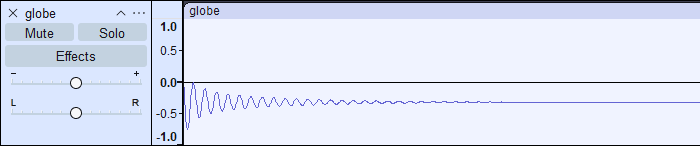

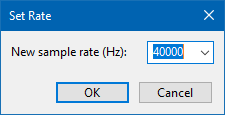

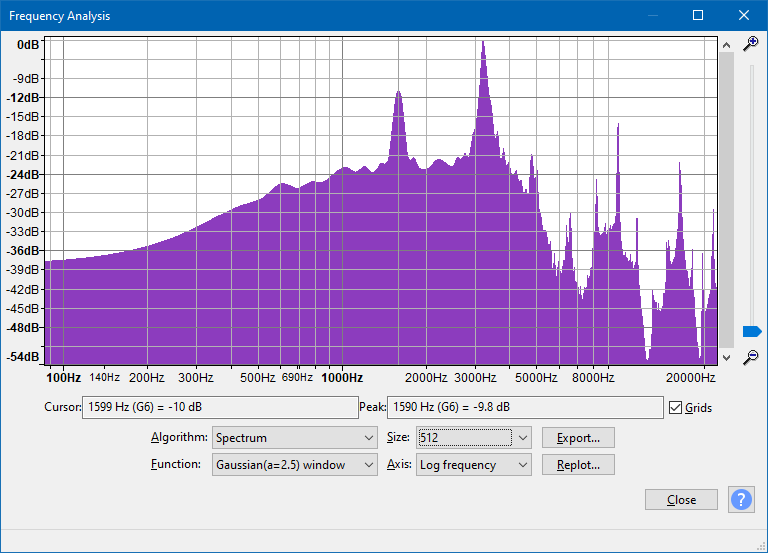

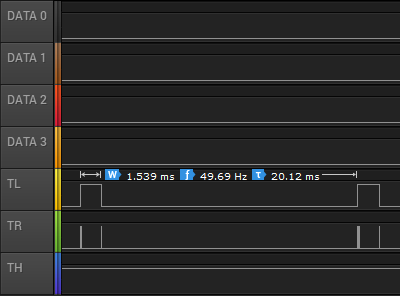

Why does it look so spiky, though? It would only need to look like that if it had been sampled at an extremely low rate, and indeed that's what I found – these files are recorded at a 5kHz sample rate:

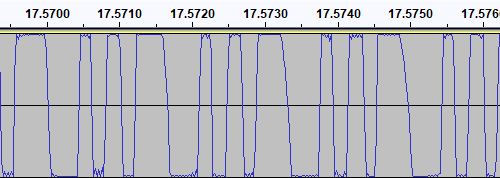

5kHz is a pretty unusual (and very low!) sample rate that I suspected my sound card was not handling particularly gracefully. Typically audio would need to be resampled to 44.1kHz or 48kHz before playing back, so I thought I'd try resampling in Audacity. This produced this weirdness:

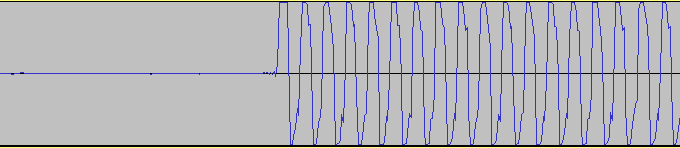

Instead of a sine wave that alternates between two frequencies, I ended up with something more akin to an amplitude-modulated signal! The high-frequency pilot also disappears entirely, apart from what looks to be some initial ringing:

Now, this is a complete guess, but I suspect that what is happening is an attempt to reduce unpleasant harmonics in the resampled audio. A square wave (such as the one we're resampling) produces a lot of harmonics at higher frequencies. As the original audio was sampled at 5kHz, the highest frequency that this could represent was 2.5kHz (alternating high and low each sample, as per the pilot tone). A low-pass filter at 2.5kHz could therefore reduce the harmonics, though I'd still expect some of it to get through (rather than it being apparently being attenuated to zero in this case!) In any case, the signal is being destroyed by the resampling process, so it's no wonder the computer can't load the data.

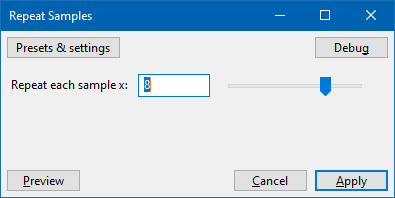

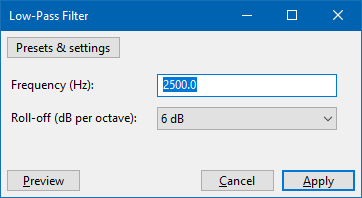

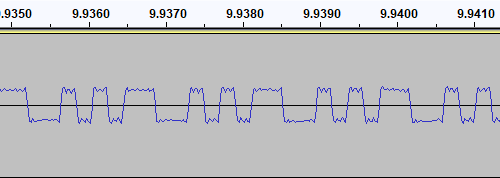

So, what's the solution? A simpler resampling algorithm that just duplicates samples (a sort of "nearest neighbour") should give us an acceptable square wave when processing, however I could not find any way to achieve this natively in Audacity. Fortunately, though, there's a Nyquist Plugin script that can be used to repeat all samples (install via Tools→Nyquish Plugin Installer, then check it's listed in Tools→Plugin Manager – it will appear as Effect→Repeat Samples). As we want to end up around 44.1kHz the plugin can be used to repeat each sample eight times, which would take our 5kHz sample rate to 40kHz:

↓

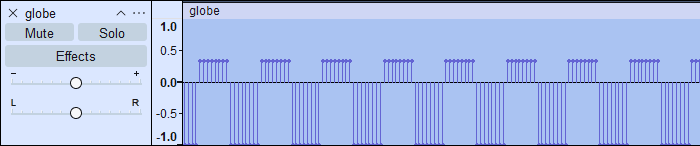

When played back the pilot tone can finally be heard, but it's at much too low a pitch! This is because the samples have been repeated eight times, but the track's sample rate hasn't been increased to match. This can be done by right-clicking the track and selecting Rate→Other and entering 40kHz:

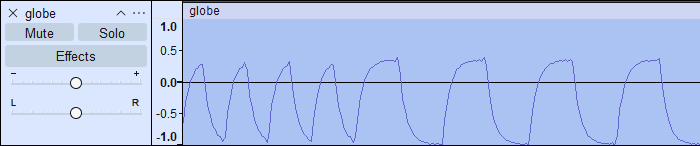

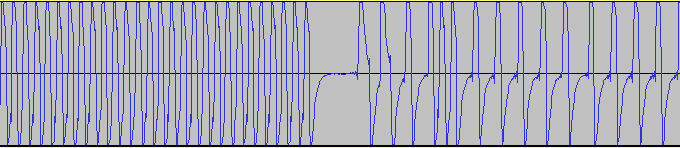

Now when the clip is played back it sounds as it should. As a further experiment, the sample rate could be changed from its somewhat odd 40kHz to a more conventional 44.1kHz via Tracks→Resample. When this is done, the nice clean square wave loses definition again:

As I mentioned earlier, square waves have a lot of harmonics, and the resampling process makes these harmonics extremely visible riding on top and bottom of each cycle of the square wave. There is one way to clean this up quite nicely, however – as we want to cull high-frequency harmonics, and as the original recording could only represent frequencies up to 2.5kHz we can apply a low-pass filter at 2.5kHz from the Effects menu:

↓

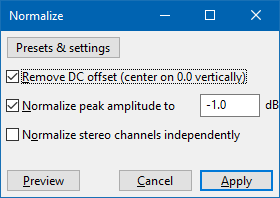

This resulting file sounds much better and loads into the computer as it should. It's a bit of a convoluted process, but it does at least bypass the resampling weirdness that distorts the original files in such a way that they can't be loaded. The only additional step I might recommend is to more neatly balance the signal around zero by normalising it as the first step:

In summary, the steps are as follows:

- Normalise the file (Effect→Normalize)

- Repeat all samples by 8× (Effect→Repeat Samples)

- Set track sample rate to 8× what it was (right-click, Rate→Other, multiply the value by 8)

- Resample to 44.1kHz (Tracks→Resample)

- Low-pass filter at 2.5kHz (Effect→Low-Pass Filter)

Happy tape loading!

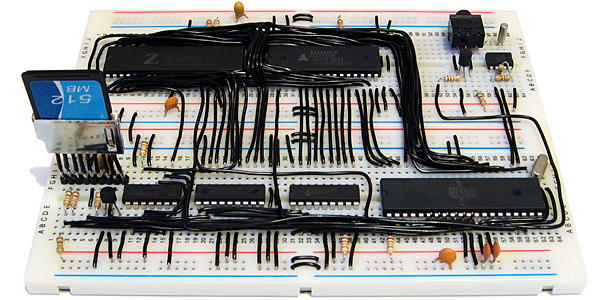

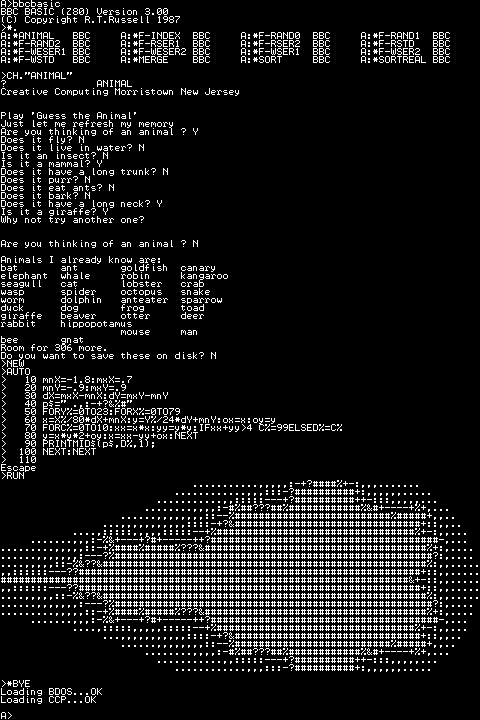

1-Wire interfacing with the Cambridge Z88

Sunday, 17th December 2023

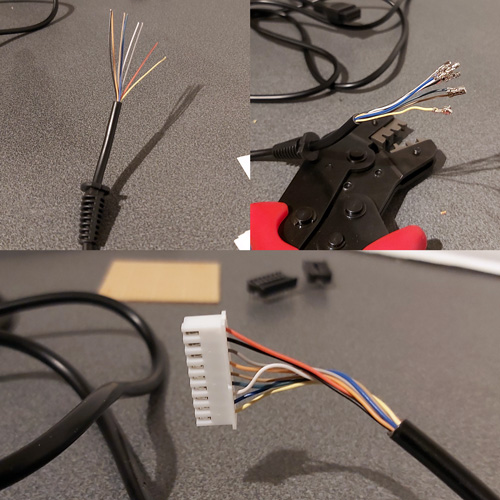

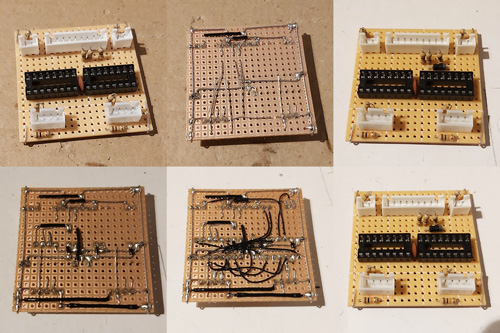

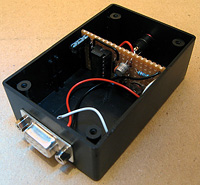

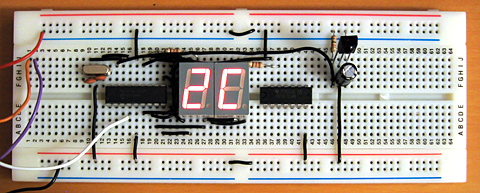

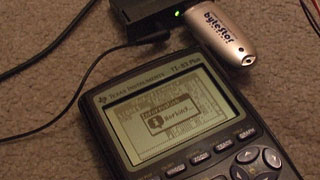

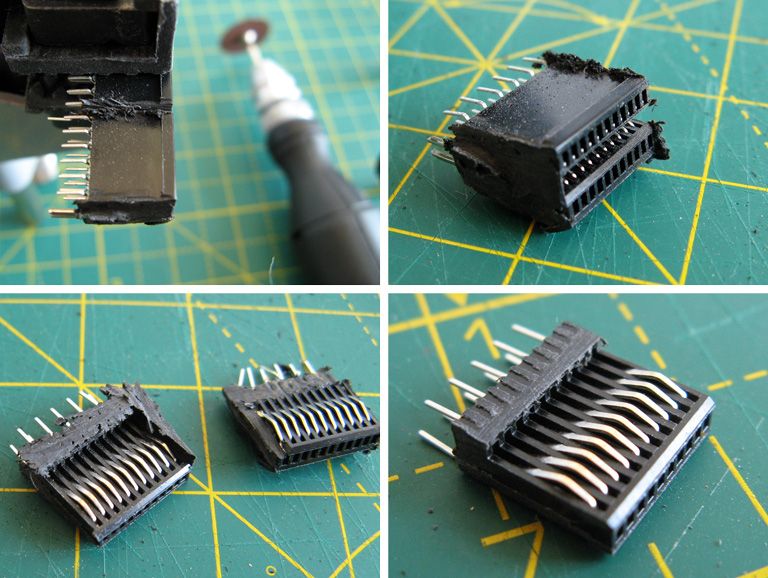

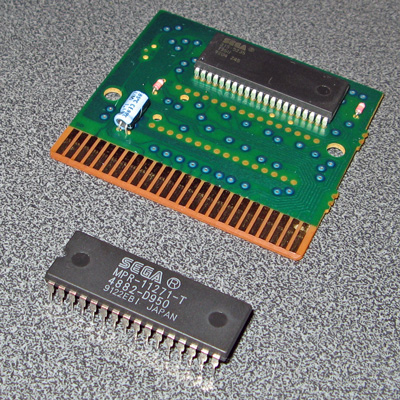

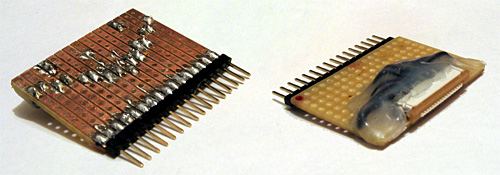

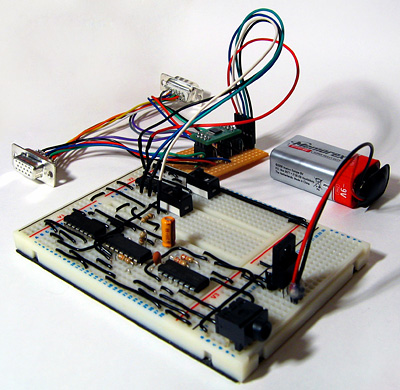

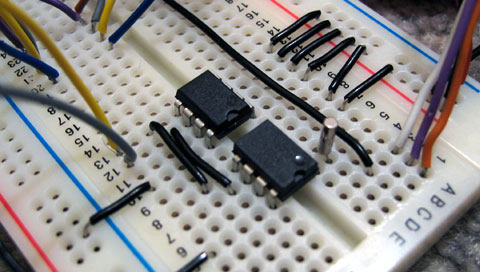

I've been having a tricky time buying LM35DZ analogue temperature sensors for a project recently. One pair of probes and a bag of loose components labelled LM35DZ turned out to be regular NPN transistors with a fake label on them, and another pair of probes ended up being DS18B20 digital temperature sensors.

Whilst the DS18B20 temperature sensors were useless for the project I had in mind they were still functioning components. These use the 1-Wire serial bus, a bus named for the way that its single data line can also be used to parasitically power the devices on the bus. Electrically the bus is open drain with a pull-up resistor that idles in the high state which any device can drive low. The master initiates all communication and you can have multiple peripheral devices connected to the bus in an arrangement called a MicroLAN.

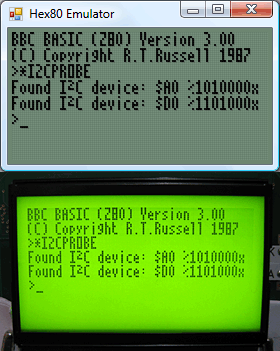

I'd had some limited experience working with the 1-Wire bus as part of my version of the Superprobe but now that I had a collection of temperature sensors I thought it might be worth revisiting, this time on the Cambridge Z88.

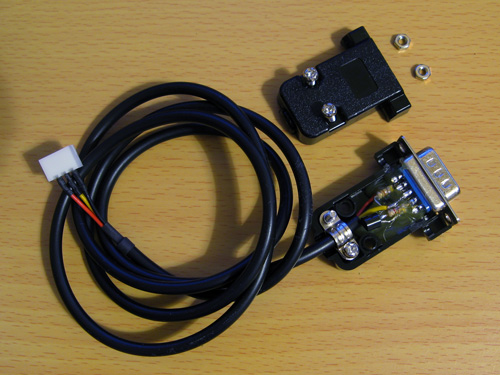

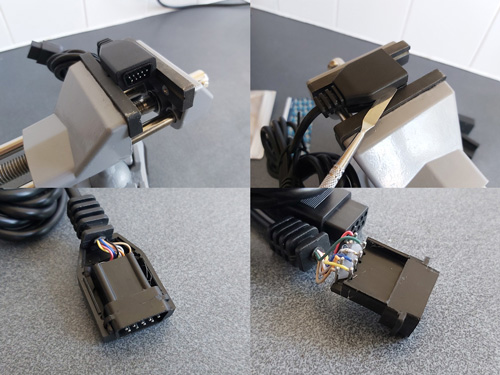

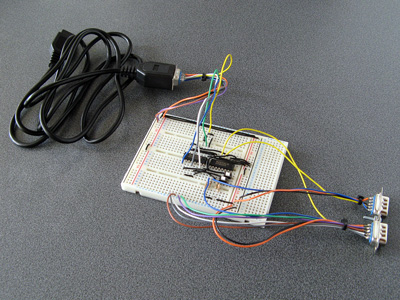

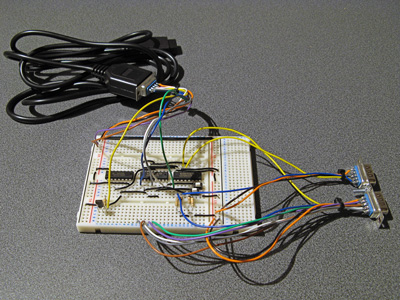

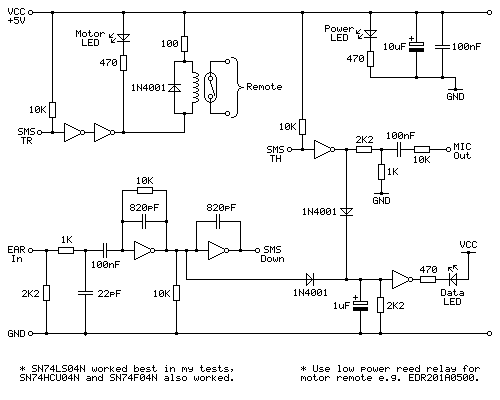

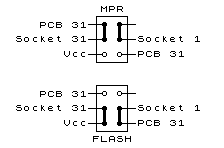

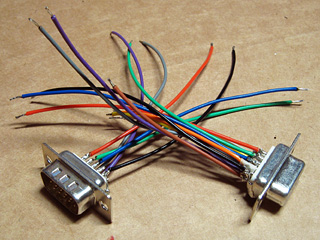

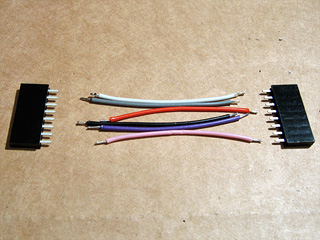

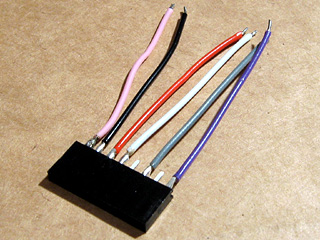

1-Wire adaptor for the Z88 serial port

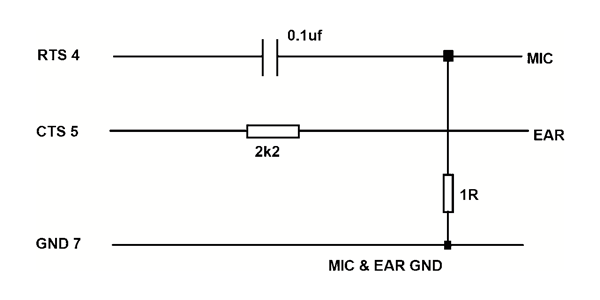

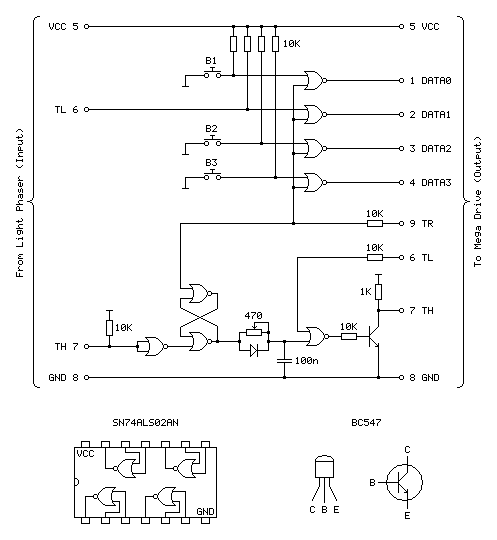

To connect 1-Wire devices to the Z88 some sort of adaptor is required and one that plugged into the computer's serial port seemed like a sensible enough option. The Z88's serial port hardware normally handles all the communications for you however it is possible to directly control the logic levels of the serial port's output pins and read back the status of the input pins via some hardware registers.

The TXD line can be +5V for a logic 0 and -6V for a logic 1, adhering to the RS-232 standard. When idle TXD is in its logic 1 state, outputting -6V. Bit ITX (3) in the TXC (&E4) register can be used to invert the behaviour of the TXD pin, so by setting this bit we can change the state of the pin from -6V to +5V.

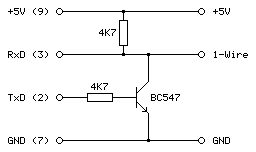

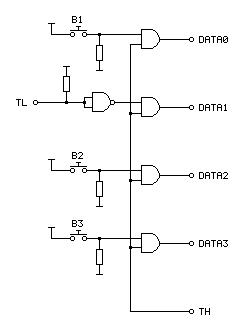

As we need to have an open-drain bus we can use an NPN transistor with the base connected to the TXD line via a current-limiting resistor, the emitter connected to ground and the collector driving the 1-Wire bus. By default the TXD pin will output -6V, the transistor will be switched off and the bus will be pulled high. When the TXD pin state is inverted it will output +5V, the transistor will switch on and drive the line low.

The state of the RXD line can be read directly via bit RXD (4) in the RXE (&E1) register. The lines appear to be weakly held to 0V and read back a 0 bit in this state, flipping to a 1 bit when the voltage rises above around 2V. In this case we can connect the 1-Wire bus directly to the RXD input and be able to read back the current state.

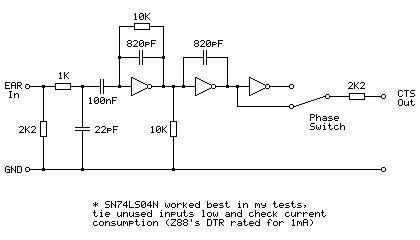

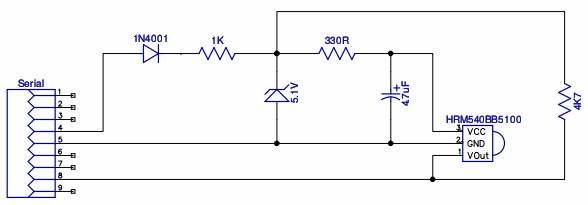

The circuit for the adaptor, including the 4.7K pull-up resistor, appears as follows:

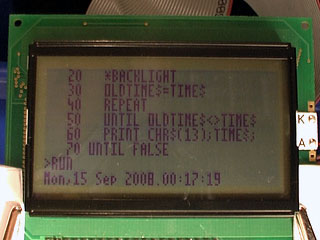

This can be tested in a BASIC program. To determine the input state we can read from the RXE port register (&E1) and check the state of the RXD bit (4):

10 RXE=&E1:M_RXERXD=&10 20 REPEAT 30 PRINT ~(GET(RXE) AND M_RXERXD) 40 UNTIL FALSE

The mask value M_RXERXD is specified as 24=&10 to correspond to the bit four. When run this program displays &10 in hex (showing bit 4 is set and the bus level is therefore high) until the 1-Wire bus line is connected to ground, when the value changes to 0 (showing bit 4 is reset and the bus level is therefore low).

To change the output state we need to write to bit ITX (3) of the TXC register (&E4). However, when writing to the hardware port we only want to change that bit and leave the others alone. The TXC register is a write-only port, so we can't retrieve its previous state by reading from the port. Fortunately the OS maintains a copy of the last value written as a "soft copy" in RAM at address &04E4 and this can be read with the ? indirection operator:

10 TXC=&E4:M_TXCITX=&08 20 SC=&400 30 TXC_OLD=SC?TXC 40 PUT TXC,TXC_OLD OR M_TXCITX 50 IF INKEY(100) 60 PUT TXC,TXC_OLD

The above program reads the old state of the TXC port from the soft copy, ORs it with the mask of the ITX bit (23=&08) and then outputs that to the TXC port. This has the effect of inverting the TXD line, driving the 1-Wire bus low. The program then waits one second with a dummy keyboard read before restoring the old value of the TXC port to release the 1-Wire bus.

Normally if changing the state of the serial port it would be good manners to update the soft copy of the serial port state however as the program is just going to be sending short low pulses before returning the port to its previous state this step is omitted.

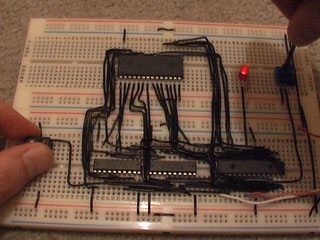

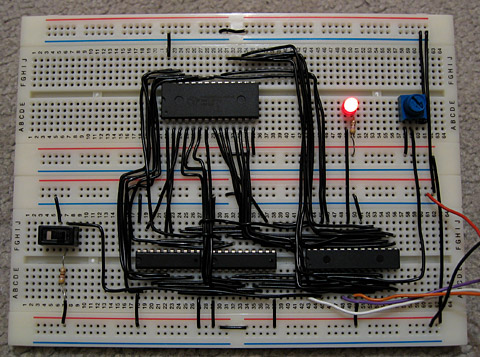

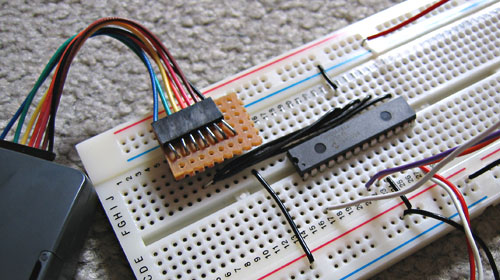

After testing that the circuit worked on a breadboard a more permanent version was assembled in a DE-9 shell as above. As the clips that hold in the DE-9 connector had to cut off to allow it to fit in the Z88's recessed port the circuit ended up being secured with copious amounts of hot glue, which is far from ideal, but nobody will see when it's all screwed back together.

Bit-level protocol

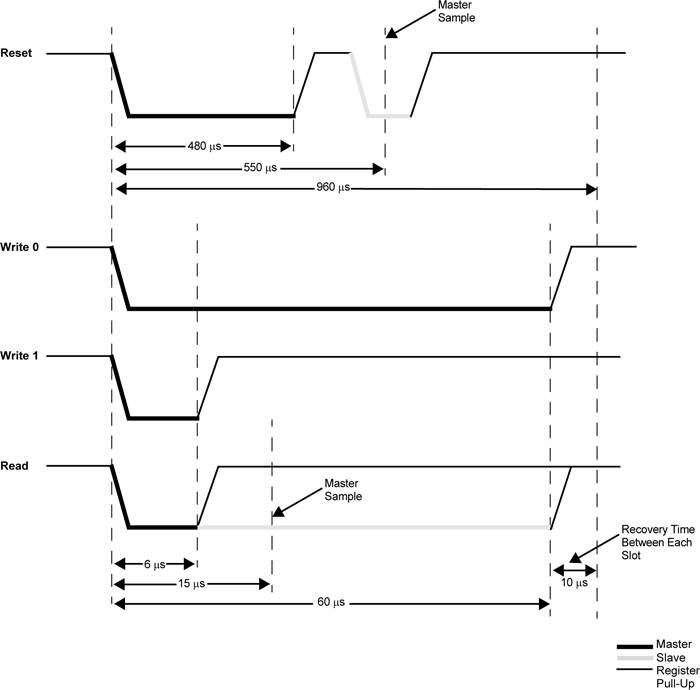

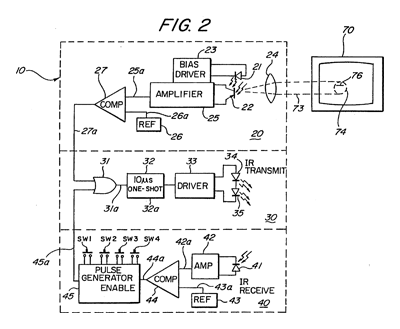

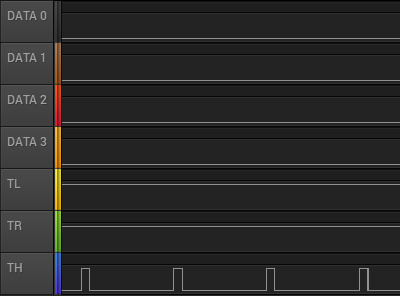

Now that we can electrically control the bus we need to know how to transfer data on it. This is done by timed pulses, where the bus master will hold the bus line low for a certain amount of time, release it, then check to see if any devices on the bus are holding it low in return. This is summarised in the following timing diagram from Microchip's AN1199, 1-Wire Communication with PIC Microcontroller:

The first thing that needs to be done is to reset all devices on the bus. This is done by holding the bus low for 480μs then releasing it for at least 480μs. If any peripheral devices are present on the bus they will drive the line low after the low pulse from the master, so the full reset procedure is as follows:

- Master drives bus low

- Delay 480μs

- Master releases bus high

- Delay 70μs

- Sample bus state: if high, no peripheral devices present, if low at least one device present.

- Delay 410μs

Once reset, data can be transmitted from the master to peripheral devices bit-by-bit in a similar fashion to the reset pulse, albeit with different timing.

To send a 0 bit:

- Master drives bus low

- Delay 60μs

- Master releases bus high

- Delay 10μs

To send a 1 bit:

- Master drives bus low

- Delay 6μs

- Master releases bus high

- Delay 64μs

Bytes are transferred as eight individual bits, least-significant bit first. The protocol is also tolerant of large delays between individual bits.

Once data has been sent to a peripheral, it may respond with data of its own. The master is still in control of clocking the data out of the peripheral, and the process is as follows:

- Master drives bus low

- Delay 6μs

- Master releases bus high

- Delay 9μs

- Sample bus state to read data bit from peripheral

- Delay 55μs

The overall timing for reading a bit is the same as the timing for sending a 1 bit (an initial 6μs low pulse from the master and a total bit time of 70μs) so in practice only one routine needs to be implemented and the value returned from the bus during read operations can be ignored during write operations.

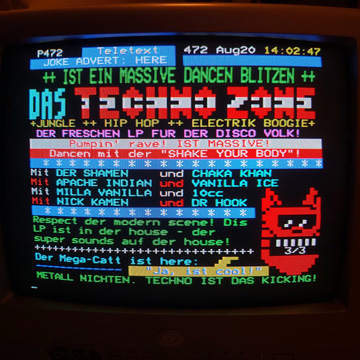

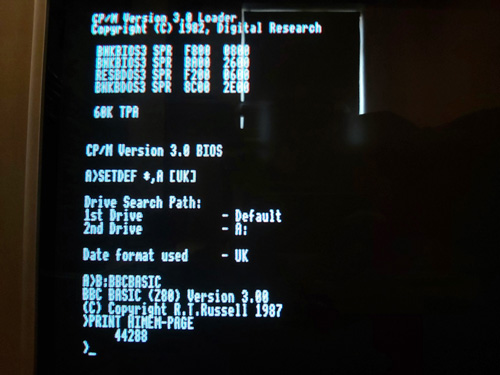

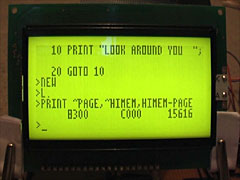

Software choice for the Z88

I thought it would be nice to be able to interact with 1-Wire devices from a BASIC program. BBC BASIC on the Z88 does provide direct access to the hardware and would make controlling the 1-Wire bus line possible, as demonstrated earlier, however I don't think it would provide the timing accuracy required to produce the appropriate pulses from the master. Fortunately it does include a Z80 assembler and so a mixture of a BASIC program that provides the high-level routines and assembly snippets for the low-level 1-Wire protocol implementation seemed like an appropriate mix of languages.

When you CALL an assembly routine from BASIC the Z80's registers are initialised to the values of the corresponding static variables, for example A is set to A%, H to H%, L to L% etc. You can't return a value directly – for that you'd need USR – however it's a bit easier to just store the return value in memory and retrieve that from BASIC after the CALL returns.

A rough starting point for the 1-Wire program is as follows:

10 REM 1-WIRE DEMO 20 PROC_1W_INIT 30 PRINT FN_1W_RESET 40 END 50 : 60 REM 1-WIRE ROUTINES 70 END 80 DEFPROC_1W_INIT 90 ow_code_size=256:DIM ow_code ow_code_size-1 100 RXE=&E1:M_RXERXD=&10 110 TXC=&E4:M_TXCITX=&08 120 SC=&400 130 FOR opt=0 TO 2 STEP 2 140 P%=ow_code 150 [OPT opt 160 .ow_buf DEFB 0 \ temporary transfer buffer 170 : 180 .ow_reset 190 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:SBC A,A:LD (ow_buf),A:RET NZ \ check bus is idle 200 DI:LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low 210 LD B,120:DJNZ P% \ delay 220 AND NOT M_TXCITX:OUT (TXC),A \ release bus 230 LD B,18:DJNZ P% \ delay 240 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:CCF:SBC A,A:LD (ow_buf),A \ sample presence 250 LD B,100:DJNZ P% \ delay 260 EI:RET 270 : 280 ] 290 NEXT 300 ENDPROC 310 : 320 REM Resets bus, retuns TRUE if any devices are present 330 DEFFN_1W_RESET:CALL ow_reset:=?ow_buf=0

The first few lines are going to be where our BASIC program is. This calls the procedure PROC_1W_INIT which will set things up by assembling any required Z80 code. It then calls FN_1W_RESET which is a function that resets the 1-Wire bus and checks to see if any devices assert their presence.

PROC_1W_INIT starts by allocating some memory for the assembled code to live, defines some constants for the IO ports and then runs through the two passes of the assembly process in a loop. Within the assembly block is a variable (ow_buf) which will be used to store data due to be returned by the assembly routines. The ow_reset assembly routine then follows – this first checks to see if the bus is idle (floating high) and if so it disables interrupts, holds the bus low for 480μs, releases the bus and waits 70μs, samples the state of the bus to check for device presence (storing the result in ow_buf), then delays another 410μs.

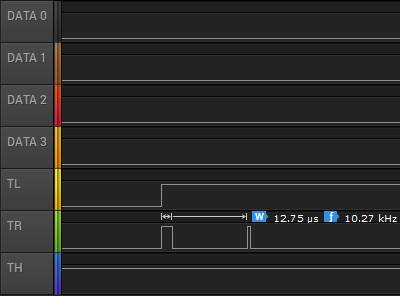

The delay loops are simple DJNZ loops with B corresponding to the length of the delay and the timings were roughly calculated first based on the number of cycles each loop would take and the Z88's 3.2768MHz CPU clock speed. They were then adjusted slightly using a logic analyser to ensure the timing was as close as could be managed to the 1-Wire protocol's specifications.

The ow_reset routine has been written so that following a successful presence check ow_buf should contain 0, and if there is a problem it will contain a non-zero value. This is used by the FN_1W_RESET wrapper function which just calls ow_reset and returns TRUE if ow_buf is zero afterwards.

If you run the program you should see that the program will display 0 (FALSE) on the screen until a 1-Wire device is connected to the adaptor, at which point it will display -1 (TRUE) instead to indicate the device's presence. This isn't a very useful program, but shows how BASIC and assembly will be mixed to build the rest of the 1-Wire routines.

Sending and receiving bits and bytes

Now that we know a device is present on the bus after a reset we need to be able to send and receive bits and bytes. Sending a 0 bit is a bit simpler than resetting, as we don't need to check for any response – just hold the line low for 60μs then release it back high for 10μs. This can be implemented as follows:

.ow_put_0 DI LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low LD B,15:DJNZ P% \ delay AND NOT M_TXCITX:OUT (TXC),A \ release bus NOP \ delay EI:RET

Sending a 1 bit has the same overall timing as reading a bit, so instead of writing separate routines to send a 1 bit and read a bit just one routine is required that handles both situations:

.ow_put_1 DI LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low NOP \ delay AND NOT M_TXCITX:OUT (TXC),A \ release bus PUSH HL:POP HL \ delay IN A,(RXE):AND M_RXERXD:SUB M_RXERXD:CCF \ sample bit LD A,(ow_buf):RRA:LD (ow_buf),A \ store bit LD B,7:DJNZ P% \ delay EI:RET

This holds the bus low for 6μs, releases it and waits 9μs, samples a bit from the bus and rotates it into the ow_buf transfer buffer, then waits 55μs.

These routines could be wrapped up for use in BASIC but it's not too useful to be able to send or receive single bits, normally we'd need to transfer whole 8-bit bytes. The ow_put_1 routine already handles updating the ow_buf with each received bit, so a byte receiving routine can be put together by just calling ow_put_1 eight times in a loop:

.ow_get_byte LD B,8 \ 8 bits to receive .ow_get_loop PUSH BC:CALL ow_put_1:POP BC \ receive single bit DJNZ ow_get_loop \ loop LD A,(ow_buf):RET \ store

A send routine can be put together with a similar loop that shifts out the bit to send and then calls either the ow_put_0 or ow_put_1 routine depending on whether it's a 0 or 1 bit that's required. Bits will usually be shifted out into the carry register, so a new ow_put_carry routine that sends the bit stored in the carry flag makes this a bit easier, e.g.

.ow_put_carry JR C,ow_put_1 JR ow_put_0

...which will be called by the ow_put_byte routine, as follows:

.ow_put_byte LD C,A:LD B,8 \ value to send in C, send 8 bits .ow_put_loop SRL C:PUSH BC:CALL ow_put_carry:POP BC \ shift and send single bit DJNZ ow_put_loop \ loop RET

It is also quite useful to be able to send or receive blocks of data at once – for example, sending or receiving the 64-bit device IDs requires sending or receiving 8 bytes of data at a time. To complement ow_get_byte and ow_put_byte we can write ow_get_bytes and ow_put_bytes routines to send or receive the block of data addressed by HL, length BC:

.ow_get_bytes LD A,B:OR C:RET Z:DEC BC \ have we finished? PUSH BC:CALL ow_get_byte:POP BC \ get a byte LD (HL),A:INC HL:JR ow_get_bytes \ store and loop : .ow_put_bytes LD A,B:OR C:RET Z:DEC BC \ have we finished? LD A,(HL):INC HL \ fetch PUSH BC:CALL ow_put_byte:POP BC:JR ow_put_bytes \ send and loop

All of these can now be wrapped up as procedures or functions so they can be more easily used from a BASIC program:

REM Transmits a single byte DEFPROC_1W_PUT(A%)CALL ow_put_byte:ENDPROC REM Transmits a block of bytes DEFPROC_1W_PUTS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_put_bytes:ENDPROC REM Receives a single byte DEFFN_1W_GET:CALL ow_get_byte:=?ow_buf REM Receives a block of bytes DEFPROC_1W_GETS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_get_bytes:ENDPROC

BASIC's integer variables are 32-bit integers so when passing the 16-bit address or length parameters the target register is the least-significant one (L for HL, C for BC) and the most-significant register (H or B) is populated by dividing the value by 256.

This can all be put together in the following demonstration program. It initialises the routines, resets the bus and checks for presence, then sends the "read ROM" command &33 which will make any connected devices respond with their ROM ID. It then reads back the eight bytes corresponding to the device ID then prints them back in hexadecimal.

10 DIM ID 7:REM Storage for device ID 20 PROC_1W_INIT 30 IF FN_1W_RESET=FALSE PRINT "No devices found.":END 40 PROC_1W_PUT(&33):REM "Read ROM" command 50 PROC_1W_GETS(ID,8):REM Read eight bytes of device ID 60 FOR I=7 TO 0 STEP -1:PRINT ~ID?I;:NEXT:PRINT:REM Print device ID bytes 70 END 80 : 90 REM 1-WIRE ROUTINES 100 END 110 DEFPROC_1W_INIT 120 ow_code_size=256:DIM ow_code ow_code_size-1 130 RXE=&E1:M_RXERXD=&10 140 TXC=&E4:M_TXCITX=&08 150 SC=&400 160 FOR opt=0 TO 2 STEP 2 170 P%=ow_code 180 [OPT opt 190 .ow_buf DEFB 0 \ temporary transfer buffer 200 : 210 .ow_reset 220 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:SBC A,A:LD (ow_buf),A:RET NZ \ check bus is idle 230 DI:LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low 240 LD B,120:DJNZ P% \ delay 250 AND NOT M_TXCITX:OUT (TXC),A \ release bus 260 LD B,18:DJNZ P% \ delay 270 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:CCF:SBC A,A:LD (ow_buf),A \ sample presence 280 LD B,100:DJNZ P% \ delay 290 EI:RET 300 : 310 .ow_put_carry 320 JR C,ow_put_1 \ fall-through 330 : 340 .ow_put_0 350 DI 360 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low 370 LD B,15:DJNZ P% \ delay 380 AND NOT M_TXCITX:OUT (TXC),A \ release bus 390 NOP \ delay 400 EI:RET 410 : 420 .ow_put_1 430 DI 440 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low 450 NOP \ delay 460 AND NOT M_TXCITX:OUT (TXC),A \ release bus 470 PUSH HL:POP HL \ delay 480 IN A,(RXE):AND M_RXERXD:SUB M_RXERXD:CCF \ sample bit 490 LD A,(ow_buf):RRA:LD (ow_buf),A \ store bit 500 LD B,7:DJNZ P% \ delay 510 EI:RET 520 : 530 .ow_put_byte 540 LD C,A:LD B,8 \ value to send in C, send 8 bits 550 .ow_put_loop 560 SRL C:PUSH BC:CALL ow_put_carry:POP BC \ shift and send single bit 570 DJNZ ow_put_loop \ loop 580 RET 590 : 600 .ow_put_bytes 610 LD A,B:OR C:RET Z:DEC BC \ have we finished? 620 LD A,(HL):INC HL \ fetch 630 PUSH BC:CALL ow_put_byte:POP BC:JR ow_put_bytes \ send and loop 640 : 650 .ow_get_byte 660 LD B,8 \ 8 bits to receive 670 .ow_get_loop 680 PUSH BC:CALL ow_put_1:POP BC \ receive single bit 690 DJNZ ow_get_loop \ loop 700 LD A,(ow_buf):RET \ store 710 : 720 .ow_get_bytes 730 LD A,B:OR C:RET Z:DEC BC \ have we finished? 740 PUSH BC:CALL ow_get_byte:POP BC \ get a byte 750 LD (HL),A:INC HL:JR ow_get_bytes \ store and loop 760 : 770 ] 780 NEXT 790 IF P%-ow_code>ow_code_size PRINT"Code size: "P%-ow_code:END 800 ENDPROC 810 : 820 REM Resets bus, retuns TRUE if any devices are present 830 DEFFN_1W_RESET:CALL ow_reset:=?ow_buf=0 840 REM Transmits a single byte 850 DEFPROC_1W_PUT(A%)CALL ow_put_byte:ENDPROC 860 REM Transmits a block of bytes 870 DEFPROC_1W_PUTS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_put_bytes:ENDPROC 880 REM Receives a single byte 890 DEFFN_1W_GET:CALL ow_get_byte:=?ow_buf 900 REM Receives a block of bytes 910 DEFPROC_1W_GETS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_get_bytes:ENDPROC

When connected to an iButton fob the program prints

55 0 0 1 A0 1A 57 1

...which matches the ID printed on it.

When connected to a DS18B20 temperature sensor the program prints

B9 0 0 1 D1 97 5D 28

The least significant byte of the 64-bit ID is the family code – &01 for the iButton fob indicates it's a "silicon serial number" type device and &28 for the DS18B20 indicates it's a "programmable resolution digital thermometer".

The 1-Wire bus supports multiple peripheral devices connected to a single master. If we try that we still get something that looks like an ID back:

11 0 0 1 80 12 55 0

This happens because it's an open-drain bus and any device holding the line low will take priority over any device releasing the line high. In effect the data read back is ANDed together, so the most-significant byte received is &55 AND &B9 which gives us the &11 we see. Fortunately that most-significant byte does give us a good opportunity to detect such invalid data!

Error detection with a CRC

Some data payloads include a CRC value. The most-significant byte of a 64-bit device ID is such a CRC, with the least-significant byte being the family code. The exact details for the CRC calculation can be found in the article Understanding and Using Cyclic Redundancy Checks with Maxim 1-Wire and iButton Products however for our purposes a Z80 implementation can be written as follows:

.ow_crc LD B,8:LD DE,(ow_buf):LD D,A \ E = accumulated CRC, D = value to add .ow_crc_loop LD A,E:XOR D:SRL D:SRL A:JR C,ow_crc_odd \ XOR and shift bits SRL E:DJNZ ow_crc_loop:LD A,E:LD (ow_buf),A:RET \ even CRC value .ow_crc_odd:SRL E:LD A,&8C:XOR E:LD E,A:DJNZ ow_crc_loop:LD (ow_buf),A:RET \ odd CRC value : .ow_crc_block XOR A:LD (ow_buf),A \ reset CRC .ow_crc_block_loop LD A,B:OR C:LD A,(ow_buf):RET Z:DEC BC \ have we finished? LD A,(HL):INC HL:PUSH BC:CALL ow_crc:POP BC:JR ow_crc_block_loop \ update CRC

ow_crc updates the current calculated CRC value (stored in ow_buf) with the next data byte from the accumulator. ow_crc_block calculates the CRC for a block of data pointed to by HL, length BC, using the ow_crc routine. A couple of BASIC functions can then be written, one to calculate the CRC of a block of data and another to check that the last byte of the block corresponds to the CRC of the preceding data:

REM Calculates the CRC of a block of data DEFFN_1W_CRC(L%,C%)LOCAL H%,B%:H%=L% DIV256:B%=C%DIV256:CALL ow_crc_block:=?ow_buf REM Checks if a CRC at the end of a block of data matches DEFFN_1W_CRC_CHECK(L%,C%)=FN_1W_CRC(L%,C%)=(L%?C%)

These two can now be used to check that a device ID is valid. The CRC is also appended to other data reports, such as reading the scratchpad memory of a temperature sensor, so it's a useful routine to have. A new program which checks the CRC is as follows:

10 DIM ID 7

20 PROC_1W_INIT

30 REPEAT

40 REPEAT UNTIL FN_1W_RESET:REM Wait for device to be present

50 PROC_1W_PUT(&33):REM Read ROM

60 PROC_1W_GETS(ID,8):REM Fetch ID

70 IF FN_1W_CRC_CHECK(ID,7) VDU 7:PRINT "Detected ";FN_1W_ID$(ID);" at ";TIME$:REM Print if valid

80 REPEAT UNTIL FN_1W_RESET=FALSE:REM Wait for device to be disconnected

90 UNTIL FALSE

100 END

110 :

120 REM 1-WIRE ROUTINES

130 END

140 DEFPROC_1W_INIT

150 ow_code_size=256:DIM ow_code ow_code_size-1

160 RXE=&E1:M_RXERXD=&10

170 TXC=&E4:M_TXCITX=&08

180 SC=&400

190 FOR opt=0 TO 2 STEP 2

200 P%=ow_code

210 [OPT opt

220 .ow_buf DEFB 0 \ temporary transfer buffer

230 .ow_conf DEFB 0 \ stores last bit conflict index

240 :

250 .ow_reset

260 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:SBC A,A:LD (ow_buf),A:RET NZ \ check bus is idle

270 DI:LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

280 LD B,120:DJNZ P% \ delay

290 AND NOT M_TXCITX:OUT (TXC),A \ release bus

300 LD B,18:DJNZ P% \ delay

310 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:CCF:SBC A,A:LD (ow_buf),A \ sample presence

320 LD B,100:DJNZ P% \ delay

330 EI:RET

340 :

350 .ow_put_carry

360 JR C,ow_put_1 \ fall-through

370 :

380 .ow_put_0

390 DI

400 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

410 LD B,15:DJNZ P% \ delay

420 AND NOT M_TXCITX:OUT (TXC),A \ release bus

430 NOP \ delay

440 EI:RET

450 :

460 .ow_put_1

470 DI

480 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

490 NOP \ delay

500 AND NOT M_TXCITX:OUT (TXC),A \ release bus

510 PUSH HL:POP HL \ delay

520 IN A,(RXE):AND M_RXERXD:SUB M_RXERXD:CCF \ sample bit

530 LD A,(ow_buf):RRA:LD (ow_buf),A \ store bit

540 LD B,7:DJNZ P% \ delay

550 EI:RET

560 :

570 .ow_put_byte

580 LD C,A:LD B,8 \ value to send in C, send 8 bits

590 .ow_put_loop

600 SRL C:PUSH BC:CALL ow_put_carry:POP BC \ shift and send single bit

610 DJNZ ow_put_loop \ loop

620 RET

630 :

640 .ow_put_bytes

650 LD A,B:OR C:RET Z:DEC BC \ have we finished?

660 LD A,(HL):INC HL \ fetch

670 PUSH BC:CALL ow_put_byte:POP BC:JR ow_put_bytes \ send and loop

680 :

690 .ow_get_byte

700 LD B,8 \ 8 bits to receive

710 .ow_get_loop

720 PUSH BC:CALL ow_put_1:POP BC \ receive single bit

730 DJNZ ow_get_loop \ loop

740 LD A,(ow_buf):RET \ store

750 :

760 .ow_get_bytes

770 LD A,B:OR C:RET Z:DEC BC \ have we finished?

780 PUSH BC:CALL ow_get_byte:POP BC \ get a byte

790 LD (HL),A:INC HL:JR ow_get_bytes \ store and loop

800 :

810 .ow_crc

820 LD B,8:LD DE,(ow_buf):LD D,A \ E = accumulated CRC, D = value to add

830 .ow_crc_loop

840 LD A,E:XOR D:SRL D:SRL A:JR C,ow_crc_odd \ XOR and shift bits

850 SRL E:DJNZ ow_crc_loop:LD A,E:LD (ow_buf),A:RET \ even CRC value

860 .ow_crc_odd:SRL E:LD A,&8C:XOR E:LD E,A:DJNZ ow_crc_loop:LD (ow_buf),A:RET \ odd CRC value

870 :

880 .ow_crc_block

890 XOR A:LD (ow_buf),A \ reset CRC

900 .ow_crc_block_loop

910 LD A,B:OR C:LD A,(ow_buf):RET Z:DEC BC \ have we finished?

920 LD A,(HL):INC HL:PUSH BC:CALL ow_crc:POP BC:JR ow_crc_block_loop \ update CRC

930 ]

940 NEXT

950 IF P%-ow_code>ow_code_size PRINT"Code size: "P%-ow_code:END

960 ENDPROC

970 :

980 REM Resets bus, retuns TRUE if any devices are present

990 DEFFN_1W_RESET:CALL ow_reset:=?ow_buf=0

1000 REM Transmits a single byte

1010 DEFPROC_1W_PUT(A%)CALL ow_put_byte:ENDPROC

1020 REM Transmits a block of bytes

1030 DEFPROC_1W_PUTS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_put_bytes:ENDPROC

1040 REM Receives a single byte

1050 DEFFN_1W_GET:CALL ow_get_byte:=?ow_buf

1060 REM Receives a block of bytes

1070 DEFPROC_1W_GETS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_get_bytes:ENDPROC

1080 :

1090 REM Converts ID bytes into string

1100 DEFFN_1W_ID$(ID)LOCAL I%:S$="":FOR I%=7 TO 0 STEP -1:IF ID?I%>15:S$=S$+STR$~(ID?I%):NEXT:=S$:ELSE:S$=S$+"0"+STR$~(ID?I%):NEXT:=S$

1110 REM Converts string into ID bytes

1120 DEFPROC_1W_ID$(ID,ID$)LOCAL I%:FOR I%=0 TO 7:ID?I%=EVAL("&"+MID$(ID$,15-I%*2,2)):NEXT:ENDPROC

1130 :

1140 REM Calculates the CRC of a block of data

1150 DEFFN_1W_CRC(L%,C%)LOCAL H%,B%:H%=L% DIV256:B%=C%DIV256:CALL ow_crc_block:=?ow_buf

1160 REM Checks if a CRC at the end of a block of data matches

1170 DEFFN_1W_CRC_CHECK(L%,C%)=FN_1W_CRC(L%,C%)=(L%?C%)The program waits for a device to be present, reads its ID, then prints it to the screen along with the date and time if its CRC is valid. It then waits for the device to be removed before looping around to check again. This allows you to tap iButtons to a reader and it will display the relevant ID, for example. It also adds a couple of utility routines – a function, FN_1W_ID$(ID), which turns a block of ID data bytes into a string and a procedure, PROC_1W_ID$(ID,ID$), which does the opposite.

Enumerating the 1-Wire bus

It's certainly useful to be able to detect a single device on the 1-Wire bus however it would be more useful to detect multiple devices and be able to address them individually. Checking every single possible 64-bit address for a response would take far too long, but fortunately there is a way to very quickly enumerate every peripheral device on the bus by means of a binary search.

To start the search, the master sends either the normal search command &F0 or the alarm/conditional search command &EC. When using the conditional search only devices that are in some sort of alarm state will respond, allowing the master to more quickly identify the devices that need attention. As we're interested in all devices we'll use the normal search command &F0.

After issuing the search command all active devices on the bus will start to report their ID, bit by bit. Each device will send each bit twice, firstly in its normal state and then again in an inverted state. Due to the open-drain nature of the bus, this allows the master to detect conflicting bit values – if all active devices have a 0 in the current bit position then the bus will read 0 then 1, if all active devices have a 1 in the current bit position then the bus will read 1 then 0 but if there is a mixture of zeroes and ones then the bus will read 0 then 0.

After this the master sends a single bit that tells the active peripheral devices which bit it has identified. If this does not match the peripheral's current bit value then the peripheral will go into an idle state and stop responding until the bus is reset again, but if it does match then the device will continue to send bits of its ID. This allows the master to walk down both branches of the binary tree when searching for device IDs when it detects a conflict, by first selecting one bit value in one iteration of the search and then the other bit value in another iteration of the search.

The full procedure for enumerating the bus is more explicitly described in the app note 1-Wire Search Algorithm, and can be implemented with the following Z80 assembly code:

.ow_conf DEFB 0 \ stores last bit conflict index : .ow_search LD DE,(ow_conf):LD D,0:LD C,1:LD B,64 .ow_search_loop PUSH BC:CALL ow_put_1:CALL ow_put_1:POP BC:RLCA:RLCA \ get bit, !bit AND 3:JR Z,ow_search_conf \ 00 = conflict DEC A:JR Z,ow_search_1 \ 01 = 0 bit DEC A:JR Z,ow_search_0 \ 10 = 1 bit SCF:RET \ report failure .ow_search_conf LD A,B:CP E \ how does bit index compare to last conflict JR C,ow_search_0_conf \ 0, update current discrepancy JR Z,ow_search_1 \ 1, no update LD A,(HL):AND C:JR NZ,ow_search_advance \ old bit = 1, just advance LD D,B:JR ow_search_advance \ old bit = 0, update current discrepancy .ow_search_1:LD A,C:OR (HL):LD (HL),A:JR ow_search_advance .ow_search_0_conf:LD D,B \ fall-through .ow_search_0:LD A,C:CPL:AND (HL):LD (HL),A \ fall-through .ow_search_advance LD A,(HL):AND C:SUB C:CCF:PUSH BC:CALL ow_put_carry:POP BC \ return the ID bit RLC C:JR NC,P%+3:INC HL \ advance mask DJNZ ow_search_loop LD A,D:LD (ow_conf),A XOR A:LD (ow_buf),A:RET \ report success

A pair of BASIC wrappers can make using this search routine a bit easier:

REM Starts enumerating devices on the bus DEFPROC_1W_SEARCH_RESET:?ow_conf=TRUE:ENDPROC REM Searches for next device on bus. Pass search type &F0 for all devices, &EC for alarming devices. Returns TRUE if next device found DEFFN_1W_SEARCH(A%,ID)IF ?ow_conf=0:=FALSE ELSE IF FN_1W_RESET=0:=FALSE ELSE PROC_1W_PUT(A%):H%=ID DIV256:L%=ID:CALL ow_search:=?ow_buf=0

The "reset" routine just sets the last bit conflict index to -1 (TRUE=-1) and FN_1W_SEARCH will search based on the search type (&F0 for all devices, &EC for alarming devices only), the current ID and last conflict index and will return TRUE if an ID was found or FALSE if no more IDs were found.

A snippet of code that enumerates all devices on the bus and displays their IDs is as follows:

PROC_1W_SEARCH_RESET REPEAT F%=FN_1W_SEARCH(&F0,ID):IF F% PRINT FN_1W_ID$(ID) UNTIL F%=FALSE

Reading temperature sensors

So far the examples have been fairly uninteresting, but we now have enough support code to do something useful with devices on a 1-Wire network. The DS18B20 temperature sensors that inspired this whole project are probably the easiest way to show how useful the 1-Wire bus can be.

The idea here will be to search for all temperature sensors on the network and to display their current temperature reading alongside their ID on the screen. The temperature conversion is initiated by sending the "Convert T" command (&44) to the desired 1-Wire devices and then waiting for at least 750ms with the bus inactive, allowing the parasitically-powered devices enough power to complete the temperature conversion, after which the temperature can be read back from the sensor's scratchpad memory.

Due to the large delay when waiting for the sensors to handle the "Convert T" command it is easiest to send the command to all devices on the network rather than to each one individually. This can be done by first sending the "Skip ROM" command (&CC) which allows the master to skip sending a 64-bit ID to the specific device it's addressing before sending the "Convert T" command (&44). The process to tell all devices to perform a temperature conversion is as follows:

IF FN_1W_RESET=FALSE PRINT "No devices found":END REM Start temperature conversion PROC_1W_PUT(&CC):REM Skip ROM PROC_1W_PUT(&44):REM Convert T T=TIME:IF INKEY(75)>TRUE REPEAT:UNTIL TIME>T+75:REM Delay 750ms

INKEY(75) is used to delay for 750ms however as this can be skipped by pressing a key a delay loop is provided as a safety measure.

After this, all of the devices on the network are enumerated as before:

REM Search for all temperature sensors on the bus and display their readings PROC_1W_SEARCH_RESET REPEAT F%=FN_1W_SEARCH(&F0,ID) IF F% PROC_1W_PRINT_TEMP(ID) UNTIL F%=FALSE

PROC_1W_PRINT_TEMP should check to see whether the device ID corresponds to a temperature sensor (its family code, the least-significant byte, should be &28) and if so it should retrieve the temperature value and print it:

REM Print a single sensor's reading DEFPROC_1W_PRINT_TEMP(ID) LOCAL T IF ID?0<>&28 ENDPROC:REM Must be a temperature sensor T=FN_1W_READ_TEMP(ID):IF T=-999 ENDPROC:REM Read sensor and check for error @%=&20409:PRINT MID$(FN_1W_ID$(ID),3,12);":",T;" deg C":@%=&90A ENDPROC

@% controls the way numbers are printed – in this case it is changed to show four decimal places in a field width of 9 characters. When printing the device ID the first two characters and last two characters are stripped off as these correspond to the CRC and family code which are not particularly useful in this case.

FN_1W_READ_TEMP(ID) needs to fetch the temperature from the sensor with the specified ID or return -999 on error. A specific sensor can be addressed by first sending the match ROM command (&55) followed by the 64-bit device ID. After this the scratchpad RAM can be read by sending the "read scratchpad" command (&BE) then reading as many bytes as are required. We only need the first two, but will read nine as this includes all eight bytes of scratchpad RAM plus a CRC so we can verify the data is valid:

REM Retrieve a single sensor's reading DEFFN_1W_READ_TEMP(ID) LOCAL T IF FN_1W_RESET=FALSE =-999 PROC_1W_PUT(&55):PROC_1W_PUTS(ID,8):REM Match ROM PROC_1W_PUT(&BE):PROC_1W_GETS(SCRATCH,9):REM Read scratchpad IF FN_1W_CRC_CHECK(SCRATCH,8)=FALSE =-999:REM Check CRC =SCRATCH!-2DIV65536/16:REM Convert to degrees C

The final line converts the reading to °C. This is a signed 16-bit value stored in the first two bytes of the scratchpad memory. BBC BASIC's ! indirection operator reads a 32-bit value, so by reading from two bytes earlier (-2) the 16-bit temperature value is loaded into the most significant word of a 32-bit integer, and an integer divide of this by 65536 shifts this back down into the least significant word (where it should be) with the sign properly extended (so if it was a negative value before it will still be negative after the division). The value is then divided by 16 using a regular floating-point division as each unit of the temperature sensor's reported value corresponds to 1/16°C.

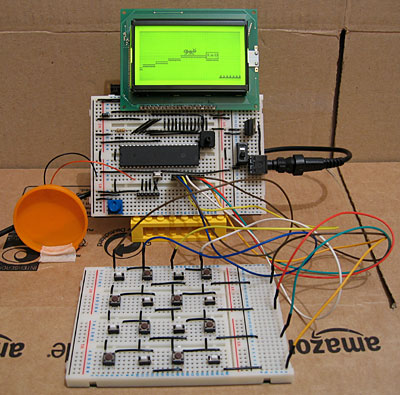

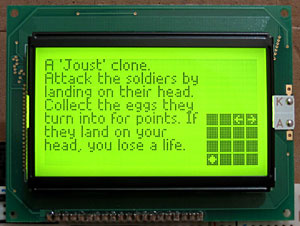

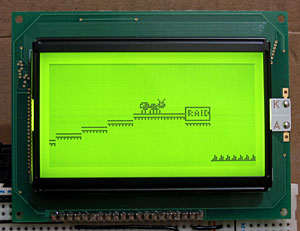

A complete demo program listing is shown below. Choosing option "3) Show DS18B20 temperatures" will show the temperatures of any connected DS18B20 temperature sensors.

10 REM 1-WIRE DEMONSTRATION FOR Z88 : BEN RYVES 2023

20 *NAME 1-Wire Demo

30 DIM ID 7,SCRATCH 8

40 PROC_1W_INIT

50 :

60 REM Main demo loop

70 REPEAT PROC_1W_DEMO_MENU

80 ON ERROR PRINT:END

90 PRINT "<Press any key>";

100 REPEAT UNTIL INKEY(0)=TRUE:IF GET

110 UNTIL FALSE

120 END

130 :

140 REM Main menu

150 DEFPROC_1W_DEMO_MENU

160 CLS:PRINT CHR$1;"1B";"1-Wire Demonstration for Cambridge Z88";CHR$1;"1B"

170 ON ERROR END

180 REPEAT

190 PRINT '"Please choose a demo: (press ESC to exit)"

200 PRINT "1) Enumerate devices"

210 PRINT "2) Scan iButton tags"

220 PRINT "3) Show DS18B20 temperatures"

230 M%=GET-ASC"0"

240 UNTIL M%>0 AND M%<4

250 ON ERROR OFF

260 PRINT

270 ON M% PROC_1W_DEMO_LIST_DEVICES, PROC_1W_DEMO_TAG, PROC_1W_DEMO_SHOW_TEMPERATURES

280 ENDPROC

290 END

300 :

310 REM Device search demo

320 DEFPROC_1W_DEMO_LIST_DEVICES

330 PROC_1W_SEARCH_RESET

340 REPEAT F%=FN_1W_SEARCH(&F0,ID):IF F% PRINT FN_1W_ID$(ID)

350 UNTIL F%=FALSE:ENDPROC

360 :

370 REM ID tag scanning demo

380 DEFPROC_1W_DEMO_TAG

390 ON ERROR GOTO 50

400 PRINT "Tap a tag on the reader (press ESC to exit)"

410 REPEAT

420 REPEAT UNTIL FN_1W_RESET:REM Wait for device to be present

430 PROC_1W_PUT(&33):REM Read ROM

440 PROC_1W_GETS(ID,8):REM Fetch ID

450 IF FN_1W_CRC_CHECK(ID,7) AND ID?0=1 VDU 7:PRINT "Detected ";FN_1W_ID$(ID);" at ";TIME$:REM Print if valid

460 REPEAT UNTIL FN_1W_RESET=FALSE:REM Wait for device to be disconnected

470 UNTIL FALSE

480 ENDPROC

490 :

500 REM Temperature demo

510 DEFPROC_1W_DEMO_SHOW_TEMPERATURES

520 IF FN_1W_RESET=FALSE PRINT "No devices found":ENDPROC

530 REM Start temperature conversion

540 PROC_1W_PUT(&CC):REM Skip ROM

550 PROC_1W_PUT(&44):REM Convert T

560 T=TIME:IF INKEY(75)>TRUE REPEAT:UNTIL TIME>T+75:REM Delay 750ms

570 REM Search for all temperature sensors on the bus and display their readings

580 PROC_1W_SEARCH_RESET

590 REPEAT F%=FN_1W_SEARCH(&F0,ID)

600 IF F% PROC_1W_PRINT_TEMP(ID)

610 UNTIL F%=FALSE

620 ENDPROC

630 REM Print a single sensor's reading

640 DEFPROC_1W_PRINT_TEMP(ID)

650 LOCAL T

660 IF ID?0<>&28 ENDPROC:REM Must be a temperature sensor

670 T=FN_1W_READ_TEMP(ID):IF T=-999 ENDPROC:REM Read sensor and check for error

680 @%=&20409:PRINT MID$(FN_1W_ID$(ID),3,12);":",T;" deg C":@%=&90A

690 ENDPROC

700 REM Retrieve a single sensor's reading

710 DEFFN_1W_READ_TEMP(ID)

720 LOCAL T

730 IF FN_1W_RESET=FALSE =-999

740 PROC_1W_PUT(&55):PROC_1W_PUTS(ID,8):REM Match ROM

750 PROC_1W_PUT(&BE):PROC_1W_GETS(SCRATCH,9):REM Read scratchpad

760 IF FN_1W_CRC_CHECK(SCRATCH,8)=FALSE =-999:REM Check CRC

770 =SCRATCH!-2DIV65536/16:REM Convert to degrees C

780 :

790 REM 1-WIRE ROUTINES

800 END

810 DEFPROC_1W_INIT

820 ow_code_size=294:DIM ow_code ow_code_size-1

830 RXE=&E1:M_RXERXD=&10

840 TXC=&E4:M_TXCITX=&08

850 SC=&400

860 FOR opt=0 TO 2 STEP 2

870 P%=ow_code

880 [OPT opt

890 .ow_buf DEFB 0 \ temporary transfer buffer

900 .ow_conf DEFB 0 \ stores last bit conflict index

910 :

920 .ow_reset

930 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:SBC A,A:LD (ow_buf),A:RET NZ \ check bus is idle

940 DI:LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

950 LD B,120:DJNZ P% \ delay

960 AND NOT M_TXCITX:OUT (TXC),A \ release bus

970 LD B,18:DJNZ P% \ delay

980 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:CCF:SBC A,A:LD (ow_buf),A \ sample presence

990 LD B,100:DJNZ P% \ delay

1000 EI:RET

1010 :

1020 .ow_put_carry

1030 JR C,ow_put_1 \ fall-through

1040 :

1050 .ow_put_0

1060 DI

1070 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

1080 LD B,15:DJNZ P% \ delay

1090 AND NOT M_TXCITX:OUT (TXC),A \ release bus

1100 NOP \ delay

1110 EI:RET

1120 :

1130 .ow_put_1

1140 DI

1150 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

1160 NOP \ delay

1170 AND NOT M_TXCITX:OUT (TXC),A \ release bus

1180 PUSH HL:POP HL \ delay

1190 IN A,(RXE):AND M_RXERXD:SUB M_RXERXD:CCF \ sample bit

1200 LD A,(ow_buf):RRA:LD (ow_buf),A \ store bit

1210 LD B,7:DJNZ P% \ delay

1220 EI:RET

1230 :

1240 .ow_put_byte

1250 LD C,A:LD B,8 \ value to send in C, send 8 bits

1260 .ow_put_loop

1270 SRL C:PUSH BC:CALL ow_put_carry:POP BC \ shift and send single bit

1280 DJNZ ow_put_loop \ loop

1290 RET

1300 :

1310 .ow_put_bytes

1320 LD A,B:OR C:RET Z:DEC BC \ have we finished?

1330 LD A,(HL):INC HL \ fetch

1340 PUSH BC:CALL ow_put_byte:POP BC:JR ow_put_bytes \ send and loop

1350 :

1360 .ow_get_byte

1370 LD B,8 \ 8 bits to receive

1380 .ow_get_loop

1390 PUSH BC:CALL ow_put_1:POP BC \ receive single bit

1400 DJNZ ow_get_loop \ loop

1410 LD A,(ow_buf):RET \ store

1420 :

1430 .ow_get_bytes

1440 LD A,B:OR C:RET Z:DEC BC \ have we finished?

1450 PUSH BC:CALL ow_get_byte:POP BC \ get a byte

1460 LD (HL),A:INC HL:JR ow_get_bytes \ store and loop

1470 :

1480 .ow_search

1490 LD DE,(ow_conf):LD D,0:LD C,1:LD B,64

1500 .ow_search_loop

1510 PUSH BC:CALL ow_put_1:CALL ow_put_1:POP BC:RLCA:RLCA \ get bit, !bit

1520 AND 3:JR Z,ow_search_conf \ 00 = conflict

1530 DEC A:JR Z,ow_search_1 \ 01 = 0 bit

1540 DEC A:JR Z,ow_search_0 \ 10 = 1 bit

1550 SCF:RET \ report failure

1560 .ow_search_conf

1570 LD A,B:CP E \ how does bit index compare to last conflict

1580 JR C,ow_search_0_conf \ 0, update current discrepancy

1590 JR Z,ow_search_1 \ 1, no update

1600 LD A,(HL):AND C:JR NZ,ow_search_advance \ old bit = 1, just advance

1610 LD D,B:JR ow_search_advance \ old bit = 0, update current discrepancy

1620 .ow_search_1:LD A,C:OR (HL):LD (HL),A:JR ow_search_advance

1630 .ow_search_0_conf:LD D,B \ fall-through

1640 .ow_search_0:LD A,C:CPL:AND (HL):LD (HL),A \ fall-through

1650 .ow_search_advance

1660 LD A,(HL):AND C:SUB C:CCF:PUSH BC:CALL ow_put_carry:POP BC \ return the ID bit

1670 RLC C:JR NC,P%+3:INC HL \ advance mask

1680 DJNZ ow_search_loop

1690 LD A,D:LD (ow_conf),A

1700 XOR A:LD (ow_buf),A:RET \ report success

1710 :

1720 .ow_crc

1730 LD B,8:LD DE,(ow_buf):LD D,A \ E = accumulated CRC, D = value to add

1740 .ow_crc_loop

1750 LD A,E:XOR D:SRL D:SRL A:JR C,ow_crc_odd \ XOR and shift bits

1760 SRL E:DJNZ ow_crc_loop:LD A,E:LD (ow_buf),A:RET \ even CRC value

1770 .ow_crc_odd:SRL E:LD A,&8C:XOR E:LD E,A:DJNZ ow_crc_loop:LD (ow_buf),A:RET \ odd CRC value

1780 :

1790 .ow_crc_block

1800 XOR A:LD (ow_buf),A \ reset CRC

1810 .ow_crc_block_loop

1820 LD A,B:OR C:LD A,(ow_buf):RET Z:DEC BC \ have we finished?

1830 LD A,(HL):INC HL:PUSH BC:CALL ow_crc:POP BC:JR ow_crc_block_loop \ update CRC

1840 ]

1850 NEXT

1860 IF P%-ow_code<>ow_code_size PRINT"Code size: "P%-ow_code:END

1870 ENDPROC

1880 :

1890 REM Resets bus, retuns TRUE if any devices are present

1900 DEFFN_1W_RESET:CALL ow_reset:=?ow_buf=0

1910 REM Transmits a single byte

1920 DEFPROC_1W_PUT(A%)CALL ow_put_byte:ENDPROC

1930 REM Transmits a block of bytes

1940 DEFPROC_1W_PUTS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_put_bytes:ENDPROC

1950 REM Receives a single byte

1960 DEFFN_1W_GET:CALL ow_get_byte:=?ow_buf

1970 REM Receives a block of bytes

1980 DEFPROC_1W_GETS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_get_bytes:ENDPROC

1990 :

2000 REM Starts enumerating devices on the bus

2010 DEFPROC_1W_SEARCH_RESET:?ow_conf=TRUE:ENDPROC

2020 REM Searches for next device on bus. Pass search type &F0 for all devices, &EC for alarming devices. Returns TRUE if next device found

2030 DEFFN_1W_SEARCH(A%,ID)IF ?ow_conf=0:=FALSE ELSE IF FN_1W_RESET=0:=FALSE ELSE PROC_1W_PUT(A%):H%=ID DIV256:L%=ID:CALL ow_search:=?ow_buf=0

2040 :

2050 REM Converts ID bytes into string

2060 DEFFN_1W_ID$(ID)LOCAL I%:S$="":FOR I%=7 TO 0 STEP -1:IF ID?I%>15:S$=S$+STR$~(ID?I%):NEXT:=S$:ELSE:S$=S$+"0"+STR$~(ID?I%):NEXT:=S$

2070 REM Converts string into ID bytes

2080 DEFPROC_1W_ID$(ID,ID$)LOCAL I%:FOR I%=0 TO 7:ID?I%=EVAL("&"+MID$(ID$,15-I%*2,2)):NEXT:ENDPROC

2090 :

2100 REM Calculates the CRC of a block of data

2110 DEFFN_1W_CRC(L%,C%)LOCAL H%,B%:H%=L% DIV256:B%=C%DIV256:CALL ow_crc_block:=?ow_buf

2120 REM Checks if a CRC at the end of a block of data matches

2130 DEFFN_1W_CRC_CHECK(L%,C%)=FN_1W_CRC(L%,C%)=(L%?C%)Temperature logger

All of this can be put together into a program that logs the temperature from any connected sensors to a CSV file on the Z88. The main loop can look similar to the one above that searches for and displays the temperature readings for any connected DS18B20 sensors, however it will instead call a PROC_1W_LOG_TEMP procedure that handles logging the data to a file instead of printing it on the display:

REM Log a single sensor's reading DEFPROC_1W_LOG_TEMP(ID) LOCAL T IF ID?0<>&28 ENDPROC:REM Must be a temperature sensor T=FN_1W_READ_TEMP(ID):IF T=-999 ENDPROC:REM Read sensor and check for error ENTRY$=FN_DATETIME$(TIME$)+","+STR$T:REM Timestamp and temperature reading ID$=MID$(FN_1W_ID$(ID),3,12):REM ID without CRC and family code CSV$=ID$+".CSV":REM Name of CSV file C=OPENUP CSV$:REM Open the CSV for update IF C=FALSE C=OPENOUT CSV$:PRINT#C,"Time,"+ID$:REM Create new CSV if required PTR#C=EXT#C:PRINT#C,ENTRY$:REM Write entry to end of CSV CLOSE#C:REM Close the CSV PRINT CSV$,ENTRY$:REM Display on screen ENDPROC

The procedure will fetch the value from the sensor and then turn the ID into a CSV filename by stripping off the CRC and family code and appending ".CSV". It will then try to open the existing file, and if one doesn't exist it will create a new one and write the column headers to it. It will then seek to the end of the file and append the timestamp and the temperature reading.

One further complication is that to make handling the CSV a bit easier, the timestamp is converted from the format returned by BBC BASIC's TIME$ function into "YYYY-MM-DD hh:mm:ss" format. This is handled by the following three functions, FN_DATE (which extracts and reformats the date component into YYYY-MM-DD format), FN_TIME (which extracts the time component into hh:mm:ss format) and FN_DATETIME which glues the date and time back together with a space in the middle:

REM Date formatting routines

DEF FN_DATE$(T$)

LOCAL C%,I%,J%,V%,R$

R$="":I%=1

FOR C%=0 TO 3 J%=INSTR(MID$(T$,I%)," ")

IF C%=2 V%=1+INSTR("JanFebMarAprMayJunJulAugSepOctNovDec",MID$(T$,I%,3))DIV3 ELSE V%=VAL(MID$(T$,I%,J%-1))

IF C%>1 R$="-"+R$

IF C% R$=STR$(V%)+R$ IF V%<10 R$="0"+R$

I%=I%+J%

NEXT

=R$

DEF FN_TIME$(T$) =MID$(T$,LEN(T$)-7)

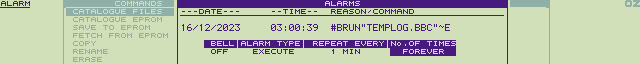

DEF FN_DATETIME$(T$) =FN_DATE$(T$)+" "+FN_TIME$(T$)One way to make this logging program more useful would be to get the computer to run it periodically (e.g. once per minute). The Z88's "Alarm" feature can execute a command whenever the alarm goes off and you can schedule recurring alarms so this sounds like an ideal starting point! When the program has run it would also be handy for the computer to switch itself off again. There is an OS call for this, OS_Off, which can be invoked from BASIC as follows:

REM SWITCH OFF ROUTINES DEFPROC_SWITCH_OFF_INIT switch_off_size=15:DIM switch_off switch_off_size-1 P%=switch_off [OPT 2 LD HL,0:ADD HL,SP:LD SP,(&1FFE):PUSH HL RST &20:DEFW &EC06:REM OS_Off POP HL:LD SP,HL:RET:] ENDPROC DEFPROC_SWITCH_OFF:CALL switch_off:ENDPROC

As with the 1-Wire assembly routines you must first call an initialisation procedure (PROC_SWITCH_OFF_INIT) to assemble the routine before calling it with PROC_SWITCH_OFF. The actual OS_Off call is the RST &20H:DEFW &EC06 in the middle of all that. Unfortunately, OS calls tend to involve some memory paging and in the process BBC BASIC's RAM gets swapped out and when the OS routine tries to return it jumps back into some different memory – the computer certainly switches off, but then it soft resets instead of coming back on properly. This is why there's some additional boilerplate code around the OS call to move the stack pointer into a safe region of memory so the routine can return properly.

The complete temperature-logging program is now shown below:

10 REM 1-WIRE TEMPERATURE LOGGER : BEN RYVES 2023

20 *NAME 1-Wire Temperature Logger

30 REPEAT UNTIL INKEY(0)=TRUE:REM Flush keyboard

40 DIM ID 7,SCRATCH 8

50 PROC_1W_INIT

60 PROC_SWITCH_OFF_INIT

70 REM Reset 1-Wire bus and check that at least one device is present

80 IF FN_1W_RESET=FALSE PROC_SWITCH_OFF:END

90 REM Start temperature conversion

100 PROC_1W_PUT(&CC):REM Skip ROM

110 PROC_1W_PUT(&44):REM Convert T

120 T=TIME:IF INKEY(75)>TRUE REPEAT:UNTIL TIME>T+75:REM Delay 750ms

130 REM Search for all temperature sensors on the bus and log their readings

140 PROC_1W_SEARCH_RESET

150 REPEAT F%=FN_1W_SEARCH(&F0,ID):IF F% PROC_1W_LOG_TEMP(ID)

160 UNTIL F%=FALSE

170 REM Switch the computer off

180 PROC_SWITCH_OFF

190 END

200 :

210 REM Log a single sensor's reading

220 DEFPROC_1W_LOG_TEMP(ID)

230 LOCAL T

240 IF ID?0<>&28 ENDPROC:REM Must be a temperature sensor

250 T=FN_1W_READ_TEMP(ID):IF T=-999 ENDPROC:REM Read sensor and check for error

260 ENTRY$=FN_DATETIME$(TIME$)+","+STR$T:REM Timestamp and temperature reading

270 ID$=MID$(FN_1W_ID$(ID),3,12):REM ID without CRC and family code

280 CSV$=ID$+".CSV":REM Name of CSV file

290 C=OPENUP CSV$:REM Open the CSV for update

300 IF C=FALSE C=OPENOUT CSV$:PRINT#C,"Time,"+ID$:REM Create new CSV if required

310 PTR#C=EXT#C:PRINT#C,ENTRY$:REM Write entry to end of CSV

320 CLOSE#C:REM Close the CSV

330 PRINT CSV$,ENTRY$:REM Display on screen

340 ENDPROC

350 REM Retrieve a single sensor's reading

360 DEFFN_1W_READ_TEMP(ID)

370 LOCAL T

380 IF FN_1W_RESET=FALSE =-999

390 PROC_1W_PUT(&55):PROC_1W_PUTS(ID,8):REM Match ROM

400 PROC_1W_PUT(&BE):PROC_1W_GETS(SCRATCH,9):REM Read scratchpad

410 IF FN_1W_CRC_CHECK(SCRATCH,8)=FALSE =-999:REM Check CRC

420 =SCRATCH!-2DIV65536/16:REM Convert to degrees C

430 :

440 REM Date formatting routines

450 DEF FN_DATE$(T$)

460 LOCAL C%,I%,J%,V%,R$

470 R$="":I%=1

480 FOR C%=0 TO 3 J%=INSTR(MID$(T$,I%)," ")

490 IF C%=2 V%=1+INSTR("JanFebMarAprMayJunJulAugSepOctNovDec",MID$(T$,I%,3))DIV3 ELSE V%=VAL(MID$(T$,I%,J%-1))

500 IF C%>1 R$="-"+R$

510 IF C% R$=STR$(V%)+R$ IF V%<10 R$="0"+R$

520 I%=I%+J%

530 NEXT

540 =R$

550 DEF FN_TIME$(T$) =MID$(T$,LEN(T$)-7)

560 DEF FN_DATETIME$(T$) =FN_DATE$(T$)+" "+FN_TIME$(T$)

570 :

580 REM SWITCH OFF ROUTINES

590 DEFPROC_SWITCH_OFF_INIT

600 switch_off_size=15:DIM switch_off switch_off_size-1

610 P%=switch_off

620 [OPT 2

630 LD HL,0:ADD HL,SP:LD SP,(&1FFE):PUSH HL

640 RST &20:DEFW &EC06

650 POP HL:LD SP,HL:RET:]

660 ENDPROC

670 DEFPROC_SWITCH_OFF:CALL switch_off:ENDPROC

680 :

690 REM 1-WIRE ROUTINES

700 END

710 DEFPROC_1W_INIT

720 ow_code_size=294:DIM ow_code ow_code_size-1

730 RXE=&E1:M_RXERXD=&10

740 TXC=&E4:M_TXCITX=&08

750 SC=&400

760 FOR opt=0 TO 2 STEP 2

770 P%=ow_code

780 [OPT opt

790 .ow_buf DEFB 0 \ temporary transfer buffer

800 .ow_conf DEFB 0 \ stores last bit conflict index

810 :

820 .ow_reset

830 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:SBC A,A:LD (ow_buf),A:RET NZ \ check bus is idle

840 DI:LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

850 LD B,120:DJNZ P% \ delay

860 AND NOT M_TXCITX:OUT (TXC),A \ release bus

870 LD B,18:DJNZ P% \ delay

880 IN A,(RXE):AND M_RXERXD:CP M_RXERXD:CCF:SBC A,A:LD (ow_buf),A \ sample presence

890 LD B,100:DJNZ P% \ delay

900 EI:RET

910 :

920 .ow_put_carry

930 JR C,ow_put_1 \ fall-through

940 :

950 .ow_put_0

960 DI

970 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

980 LD B,15:DJNZ P% \ delay

990 AND NOT M_TXCITX:OUT (TXC),A \ release bus

1000 NOP \ delay

1010 EI:RET

1020 :

1030 .ow_put_1

1040 DI

1050 LD A,(SC+TXC):OR M_TXCITX:OUT (TXC),A \ hold bus low

1060 NOP \ delay

1070 AND NOT M_TXCITX:OUT (TXC),A \ release bus

1080 PUSH HL:POP HL \ delay

1090 IN A,(RXE):AND M_RXERXD:SUB M_RXERXD:CCF \ sample bit

1100 LD A,(ow_buf):RRA:LD (ow_buf),A \ store bit

1110 LD B,7:DJNZ P% \ delay

1120 EI:RET

1130 :

1140 .ow_put_byte

1150 LD C,A:LD B,8 \ value to send in C, send 8 bits

1160 .ow_put_loop

1170 SRL C:PUSH BC:CALL ow_put_carry:POP BC \ shift and send single bit

1180 DJNZ ow_put_loop \ loop

1190 RET

1200 :

1210 .ow_put_bytes

1220 LD A,B:OR C:RET Z:DEC BC \ have we finished?

1230 LD A,(HL):INC HL \ fetch

1240 PUSH BC:CALL ow_put_byte:POP BC:JR ow_put_bytes \ send and loop

1250 :

1260 .ow_get_byte

1270 LD B,8 \ 8 bits to receive

1280 .ow_get_loop

1290 PUSH BC:CALL ow_put_1:POP BC \ receive single bit

1300 DJNZ ow_get_loop \ loop

1310 LD A,(ow_buf):RET \ store

1320 :

1330 .ow_get_bytes

1340 LD A,B:OR C:RET Z:DEC BC \ have we finished?

1350 PUSH BC:CALL ow_get_byte:POP BC \ get a byte

1360 LD (HL),A:INC HL:JR ow_get_bytes \ store and loop

1370 :

1380 .ow_search

1390 LD DE,(ow_conf):LD D,0:LD C,1:LD B,64

1400 .ow_search_loop

1410 PUSH BC:CALL ow_put_1:CALL ow_put_1:POP BC:RLCA:RLCA \ get bit, !bit

1420 AND 3:JR Z,ow_search_conf \ 00 = conflict

1430 DEC A:JR Z,ow_search_1 \ 01 = 0 bit

1440 DEC A:JR Z,ow_search_0 \ 10 = 1 bit

1450 SCF:RET \ report failure

1460 .ow_search_conf

1470 LD A,B:CP E \ how does bit index compare to last conflict

1480 JR C,ow_search_0_conf \ 0, update current discrepancy

1490 JR Z,ow_search_1 \ 1, no update

1500 LD A,(HL):AND C:JR NZ,ow_search_advance \ old bit = 1, just advance

1510 LD D,B:JR ow_search_advance \ old bit = 0, update current discrepancy

1520 .ow_search_1:LD A,C:OR (HL):LD (HL),A:JR ow_search_advance

1530 .ow_search_0_conf:LD D,B \ fall-through

1540 .ow_search_0:LD A,C:CPL:AND (HL):LD (HL),A \ fall-through

1550 .ow_search_advance

1560 LD A,(HL):AND C:SUB C:CCF:PUSH BC:CALL ow_put_carry:POP BC \ return the ID bit

1570 RLC C:JR NC,P%+3:INC HL \ advance mask

1580 DJNZ ow_search_loop

1590 LD A,D:LD (ow_conf),A

1600 XOR A:LD (ow_buf),A:RET \ report success

1610 :

1620 .ow_crc

1630 LD B,8:LD DE,(ow_buf):LD D,A \ E = accumulated CRC, D = value to add

1640 .ow_crc_loop

1650 LD A,E:XOR D:SRL D:SRL A:JR C,ow_crc_odd \ XOR and shift bits

1660 SRL E:DJNZ ow_crc_loop:LD A,E:LD (ow_buf),A:RET \ even CRC value

1670 .ow_crc_odd:SRL E:LD A,&8C:XOR E:LD E,A:DJNZ ow_crc_loop:LD (ow_buf),A:RET \ odd CRC value

1680 :

1690 .ow_crc_block

1700 XOR A:LD (ow_buf),A \ reset CRC

1710 .ow_crc_block_loop

1720 LD A,B:OR C:LD A,(ow_buf):RET Z:DEC BC \ have we finished?

1730 LD A,(HL):INC HL:PUSH BC:CALL ow_crc:POP BC:JR ow_crc_block_loop \ update CRC

1740 ]

1750 NEXT

1760 IF P%-ow_code<>ow_code_size PRINT"Code size: "P%-ow_code:END

1770 ENDPROC

1780 :

1790 REM Resets bus, retuns TRUE if any devices are present

1800 DEFFN_1W_RESET:CALL ow_reset:=?ow_buf=0

1810 REM Transmits a single byte

1820 DEFPROC_1W_PUT(A%)CALL ow_put_byte:ENDPROC

1830 REM Transmits a block of bytes

1840 DEFPROC_1W_PUTS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_put_bytes:ENDPROC

1850 REM Receives a single byte

1860 DEFFN_1W_GET:CALL ow_get_byte:=?ow_buf

1870 REM Receives a block of bytes

1880 DEFPROC_1W_GETS(L%,C%)LOCAL H%,B%:H%=L%DIV256:B%=C%DIV256:CALL ow_get_bytes:ENDPROC

1890 :

1900 REM Starts enumerating devices on the bus

1910 DEFPROC_1W_SEARCH_RESET:?ow_conf=TRUE:ENDPROC

1920 REM Searches for next device on bus. Pass search type &F0 for all devices, &EC for alarming devices. Returns TRUE if next device found

1930 DEFFN_1W_SEARCH(A%,ID)IF ?ow_conf=0:=FALSE ELSE IF FN_1W_RESET=0:=FALSE ELSE PROC_1W_PUT(A%):H%=ID DIV256:L%=ID:CALL ow_search:=?ow_buf=0

1940 :

1950 REM Converts ID bytes into string

1960 DEFFN_1W_ID$(ID)LOCAL I%:S$="":FOR I%=7 TO 0 STEP -1:IF ID?I%>15:S$=S$+STR$~(ID?I%):NEXT:=S$:ELSE:S$=S$+"0"+STR$~(ID?I%):NEXT:=S$

1970 REM Converts string into ID bytes

1980 DEFPROC_1W_ID$(ID,ID$)LOCAL I%:FOR I%=0 TO 7:ID?I%=EVAL("&"+MID$(ID$,15-I%*2,2)):NEXT:ENDPROC

1990 :

2000 REM Calculates the CRC of a block of data

2010 DEFFN_1W_CRC(L%,C%)LOCAL H%,B%:H%=L% DIV256:B%=C%DIV256:CALL ow_crc_block:=?ow_buf

2020 REM Checks if a CRC at the end of a block of data matches

2030 DEFFN_1W_CRC_CHECK(L%,C%)=FN_1W_CRC(L%,C%)=(L%?C%)When run this will log the temperatures of all connected sensors to CSV files as described above then switch the Z88 off. The "Alarm" popdown can be used to set up an alarm that runs the program once per minute (or at any other desired interval) by choosing an alarm type of "execute". This will effectively type in the supplied command, and so by setting it to #BRUN"TEMPLOG.BBC"~E it will press □+B to switch to BASIC (#B), type in RUN"TEMPLOG" and then press Enter (~E).

Setting up the alarm this way each time can be a bit tedious, so to make things easier here's a CLI file that can be used to set up the alarm:

.;Set up temperature logging alarm #A ~R~E ~D~D ##BRUN"TEMPLOG.BBC"~~E ~D ~D~R~D~R~S~U~S~U~R~D

This contains keystrokes in a similar fashion to the "command" field in the alarm settings and can be "executed" from the Z88's Filer; here #A presses □+A to enter the Alarm pop-down, ~R, ~D or ~U move the cursor right, down or up and where we need to type literal # or ~ signs they are doubled up (## or ~~). This will enter all of the required details to set up an alarm that will run the task once per minute forever, at which point they can be adjusted if required (e.g. to change the interval). Pressing Enter will create the alarm, and leaving the Alarm popdown will set it in motion. To finish data collection the Z88 can be switched back on as normal for the alarm to be cleared.

The only other point of note is that I found that the computer seemed to get a bit "gummed up" with queued keypresses. This could be because it never sits idle after handling the alarm; it runs the BASIC program then switches the computer off, waiting for the next alarm to be run. This is why a simple loop to flush the keyboard buffer occurs at the start of the program, and the computer seems much happier for it.

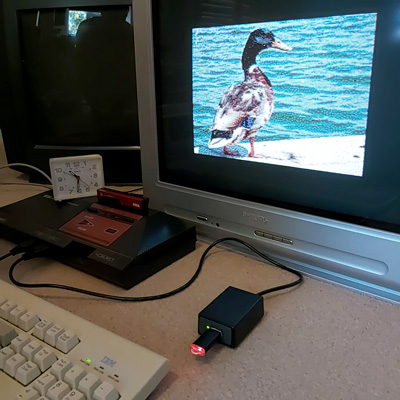

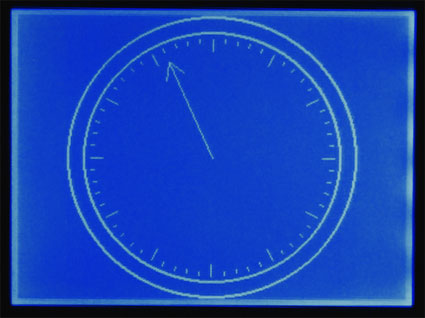

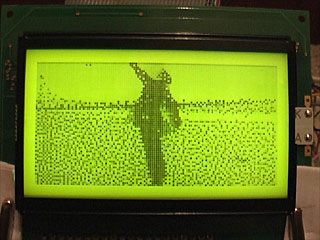

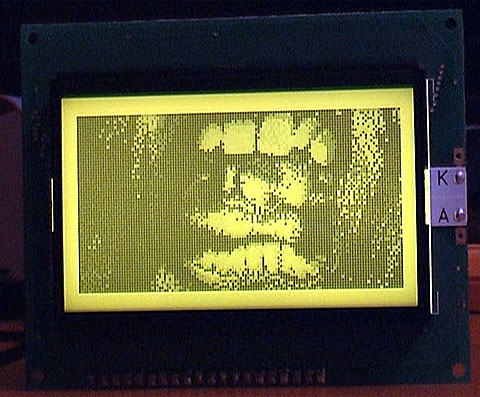

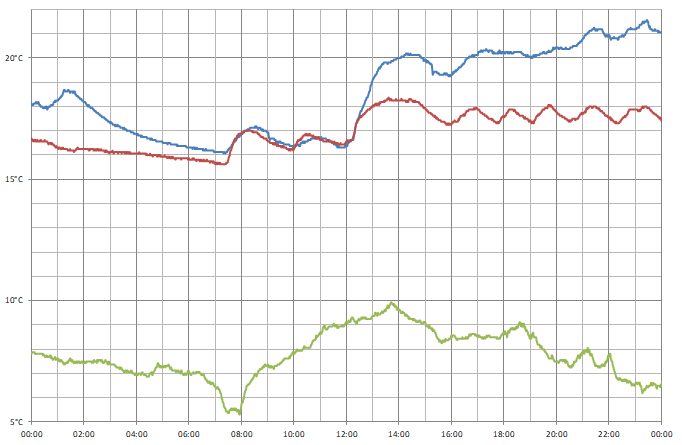

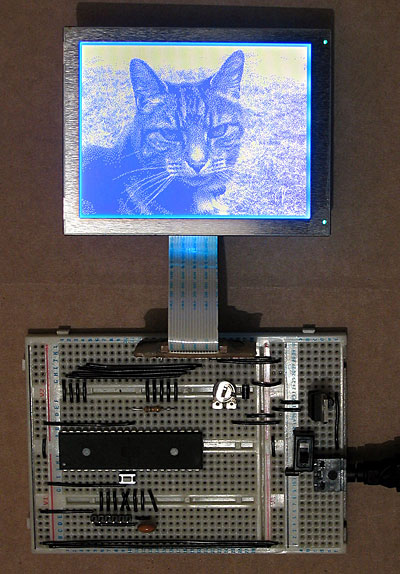

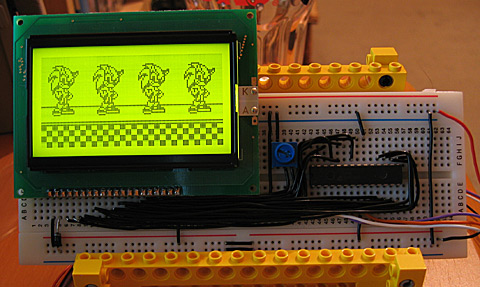

The temperature logs in the CSV files can be used to generate a chart like the following:

I captured data from three sensors over a 24 hour period; one outside (green line), one in my bedroom (red line) and one in my office (blue line). You can see how the central heating kicks in at 07:30, and I turned it up a little after 12:00. During the day the temperature in the bedroom moves up and down as the heating switches on and off, but the temperature in the office appears to be more consistent and a bit higher – the sensor is near where I am sitting and my desktop computer, which is likely contributing some heat.

Conclusion

What was originally intended to be a quick project to make use a couple of electronic components I had been sent in error soon turned into what I thought was an interesting demonstration of what can be done with the Cambridge Z88 using its stock software and some very basic additional hardware, further cementing my appreciation for the well-designed device.

The files accompanying this post can be downloaded below:

- ONEWIRE.BBC – 1-Wire demonstration program.

- TEMPLOG.BBC and TEMPLOG.CLI – Temperature logging program and CLI file to set up the alarm.

- templogs.zip and templogs.xlsx – Sample data captured by the temperature logging program.

SmartBox experimentation with DOS, RISC OS and C#/WinForms

Monday, 6th November 2023

My latest eBay purchase was influenced by a desire for some practical test/prototype equipment, a bit of nostalgia and a desire to learn something new.

A lot of my projects involve some sort of microcontroller running some software that will take inputs, perform decisions on them, and produce outputs. Getting to that stage tends to involve quite a lot of "boilerplate" hardware and software setup, and I'd quite like something that I can just plug in and get cracking with and write some quick test code instead of having to assemble a circuit on a breadboard or faff around with a clumsy IDE.

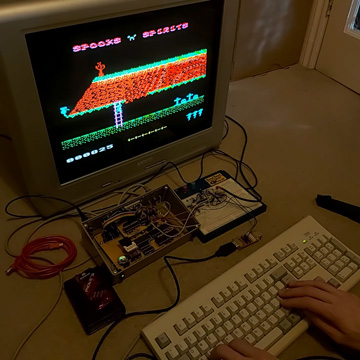

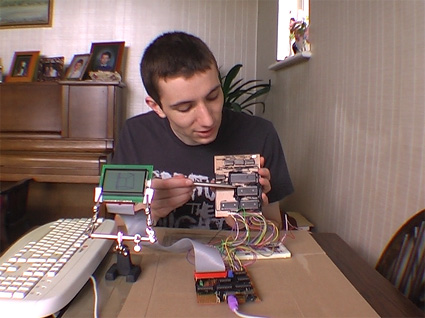

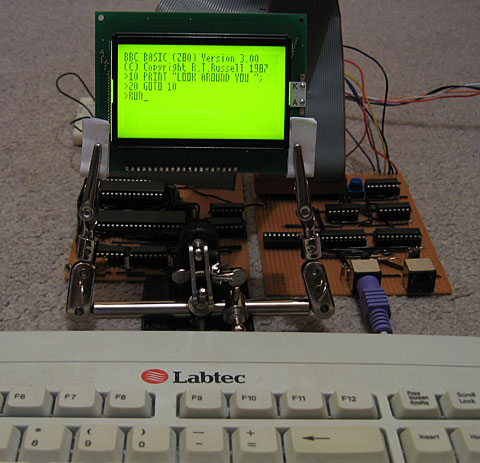

When I was at school in the 1990s one of the devices that got me into microcontrollers in the first place was a computer control system based around the Economatics SmartBox. This plugs into a computer via a serial connection, has eight simple digital inputs, eight simple digital outputs, four analogue inputs and four motor drivers. Programs could be written in a BASIC-like language or in flowchart form, and once you'd run and tested them on the SmartBox you could program them to a PIC microcontroller to run without the host computer.

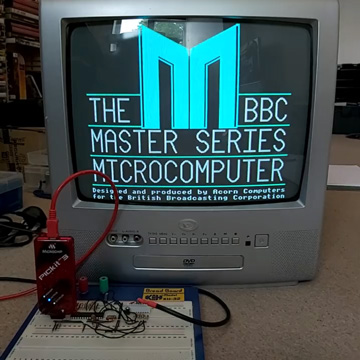

All along I'd assumed that the SmartBox was a simple interface box that relied on the host computer to do all of the processing, but doing some digging I found a thread on StarDot that delved into the heart of the machine and saw that there's a 65C02 CPU inside along with 32KB of RAM and the OS runs from a socketed 8KB ROM. As a long-term Z80 fan I thought it was time I should see how the other side lived – in spite of my fondness for the BBC Micro I don't own one and have not programmed any 6502 assembly, so a SmartBox seemed like it would also provide an affordable 6502 computer for experimentation.

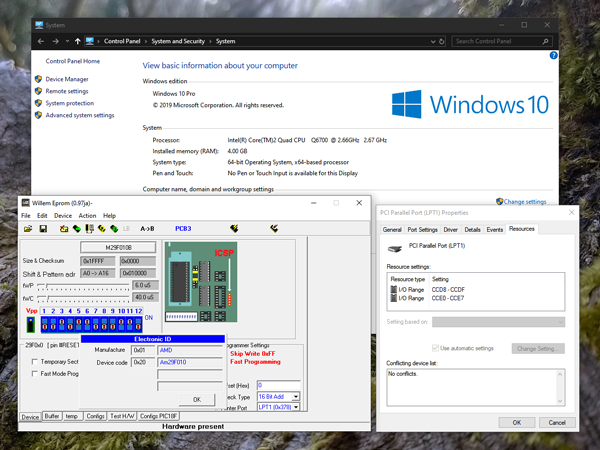

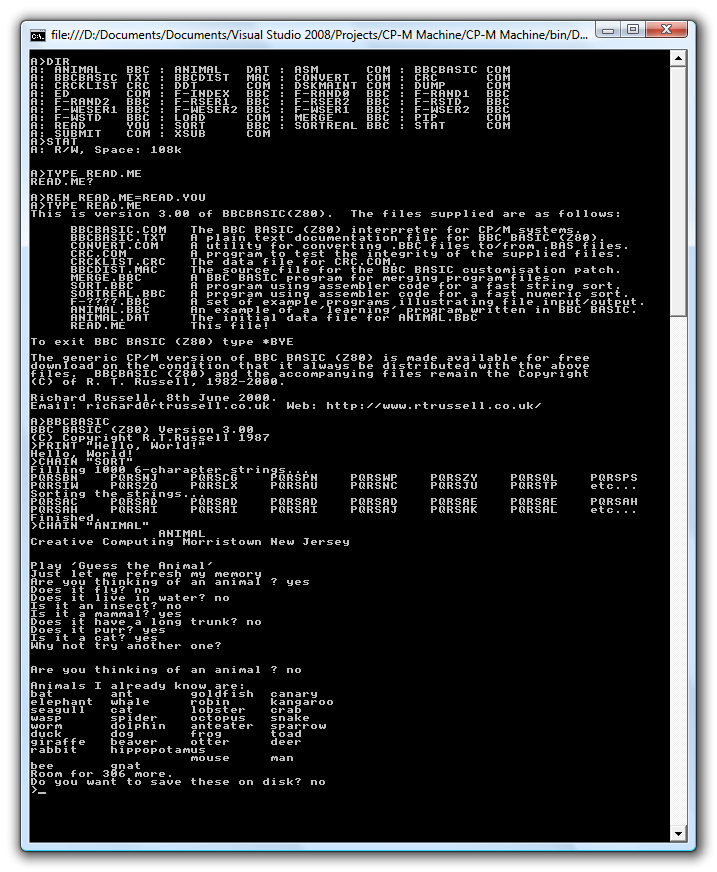

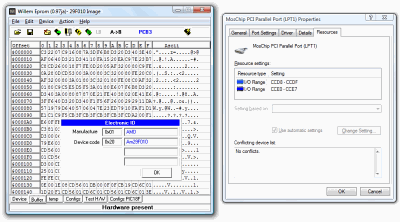

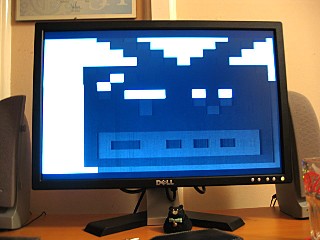

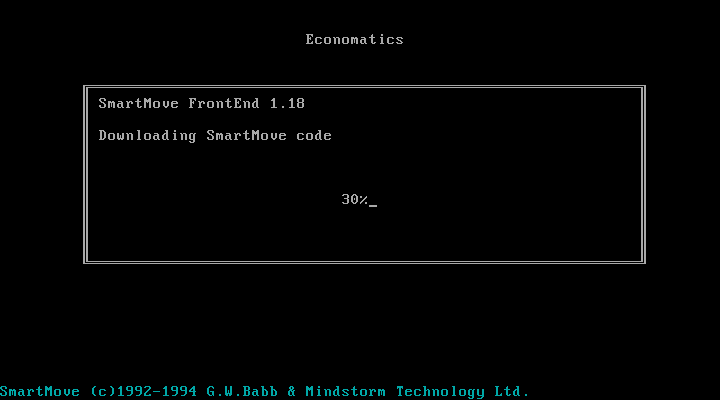

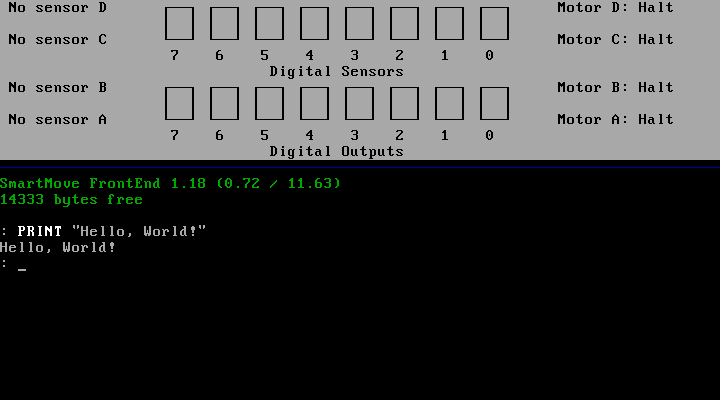

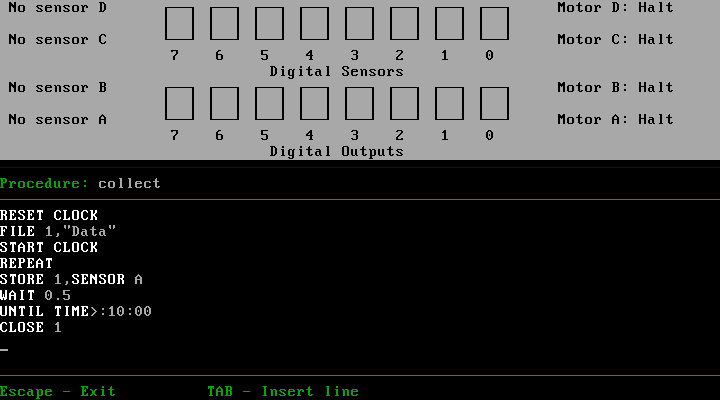

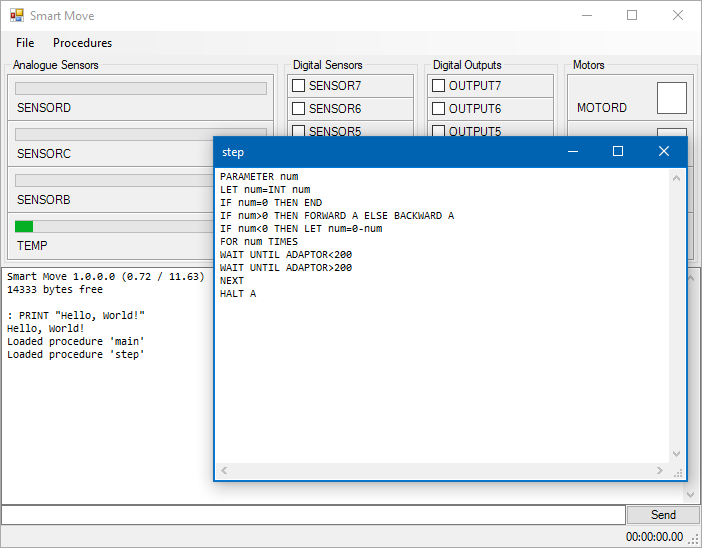

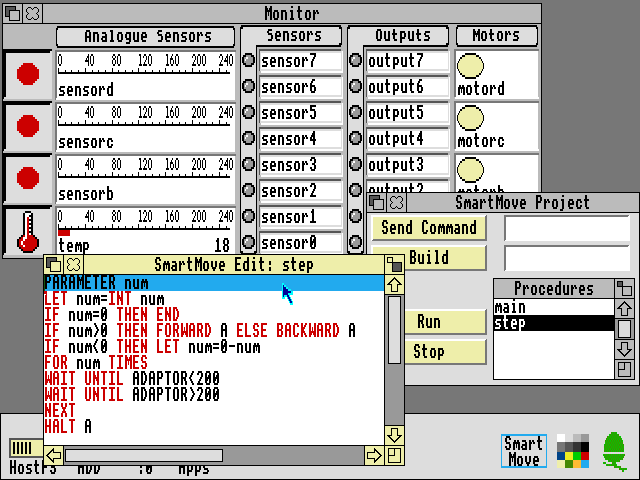

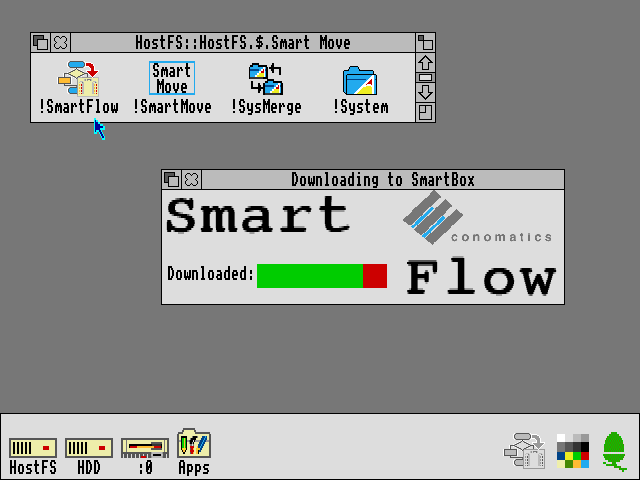

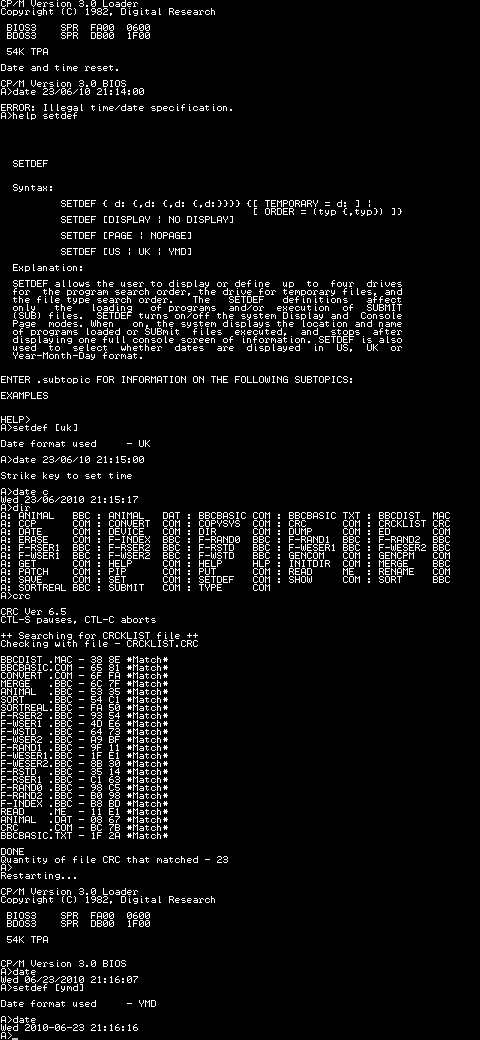

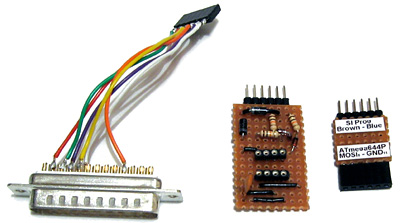

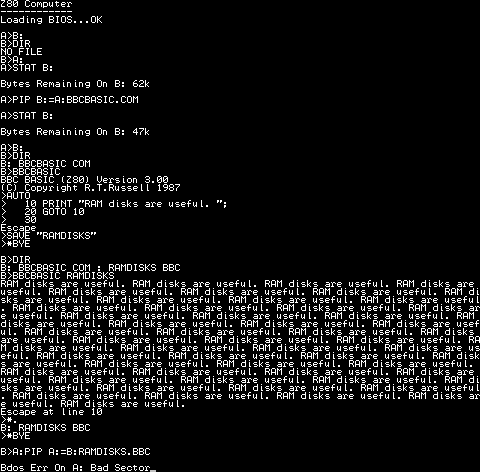

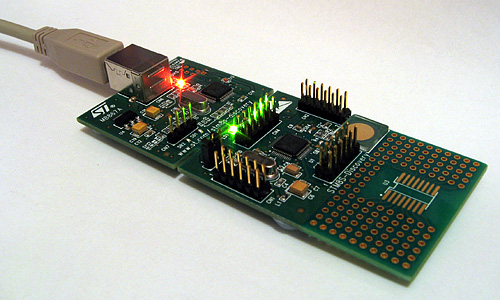

Of course, one challenge was going to be finding the supporting software for the venerable SmartBox. Fortunately in the StarDot thread people had shared archives of the DOS, BBC Master and RISC OS software. One of the many handy features of DOSBox-X is its ability to connect an emulated serial port to a physical one in the host system, and so after building a serial cable for my SmartBox (using a pinout found, once again, via the StarDot thread) I was able to hook it up to my PC and get it working with SmartMove, the BASIC-like programming environment for the SmartBox.

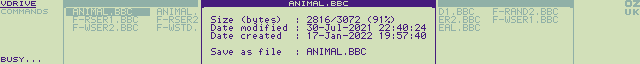

When the software is first run it needs to download SmartMove code into the SmartBox. This is because the programming environment and interpreter is actually running on the SmartBox itself, and the SmartMove software on the host PC is simply loading that interpreter onto the box (found in an accompanying file of 65C02 machine code named AL.COD) and then providing a user interface to that environment as a sort of terminal. This means you can close the SmartMove software (and unplug the serial cable) and your program will continue running on the SmartBox.

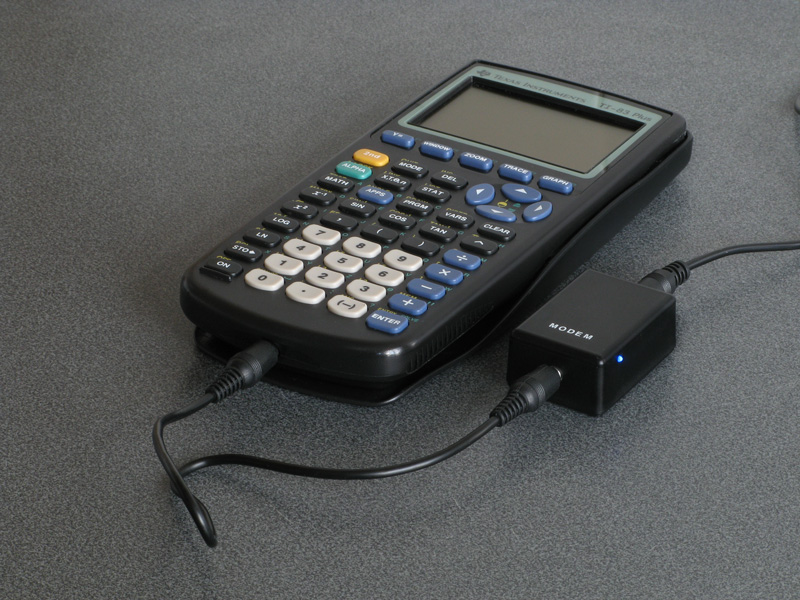

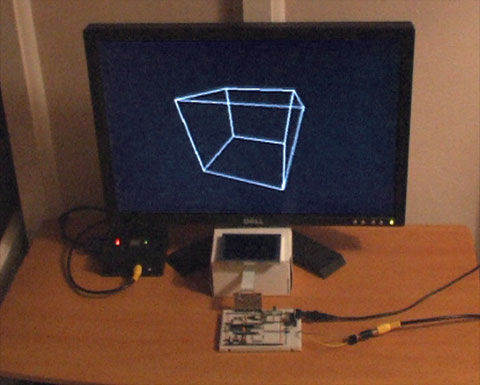

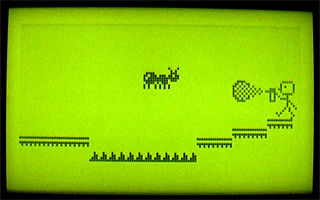

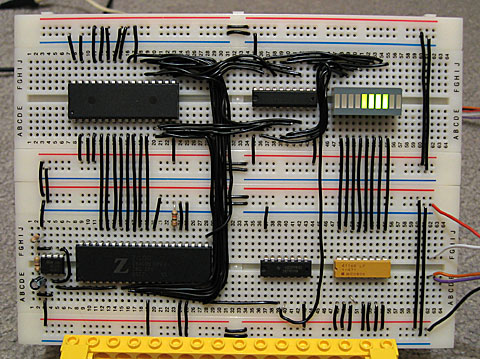

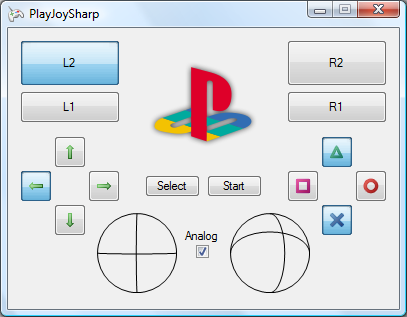

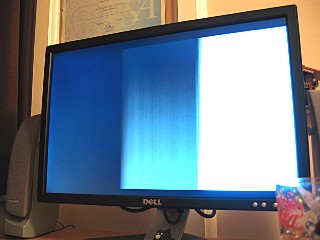

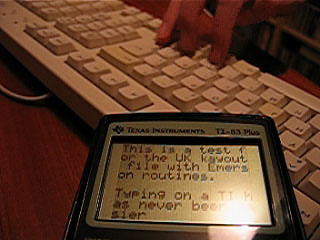

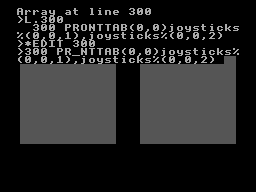

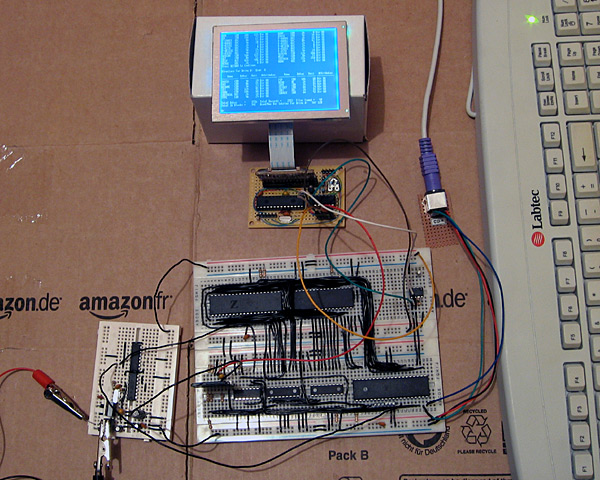

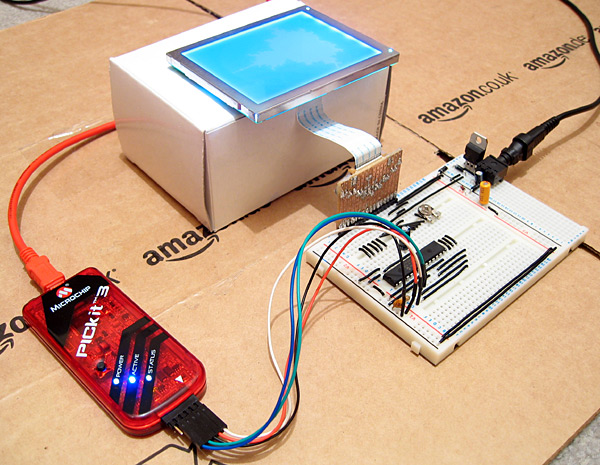

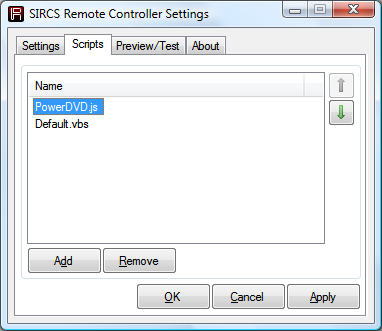

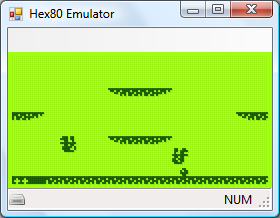

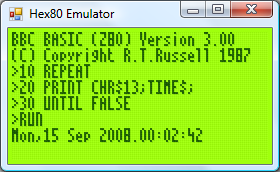

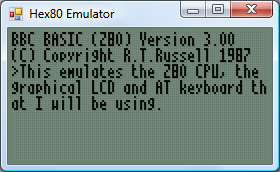

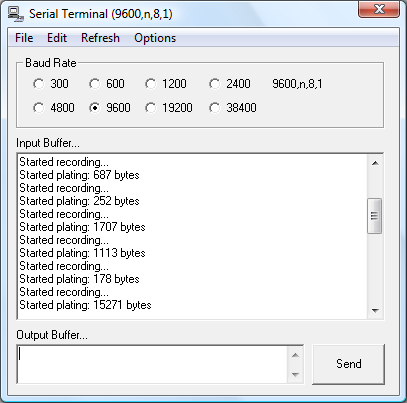

This ability to load and execute code directly on the SmartBox is one of the things that intrigued me as a way to get into 65C02 programming, but for the time being I was interested in digging deeper into the how the existing SmartMove software was interfacing with the box with the intention of writing a simple Z80 host interface that I could then adapt to the Cambridge Z88, my CP/M computer and maybe even the TI-83 Plus calculator series. Fortunately the documentation for the serial protocol used by SmartMove application has been documented so I was able to prototype a crude version of the software in C# using WinForms. It needs some serious tidying up before I can release it but as a basic test it does the job:

The ability to build new versions of the interface software for different platforms without needing to worry about porting over the BASIC interpreter seems sensible considering there were versions of SmartMove available for DOS, BBC Master, RISC OS and Apple Macintosh. All could use the same AL.COD but would just need to provide the relevant UI, input and output routines specific to their host platforms.

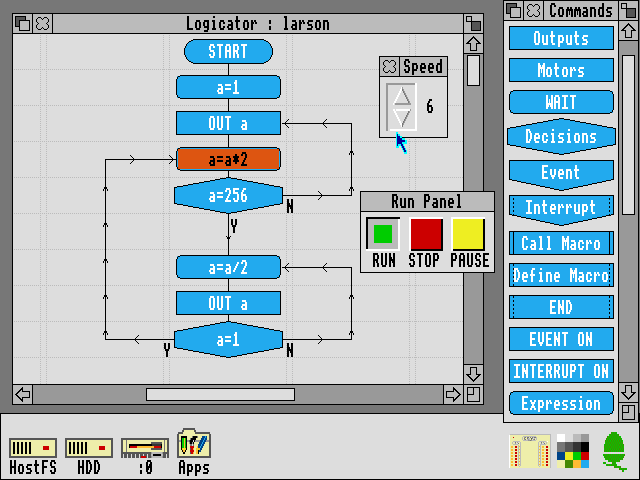

I had been using the DOS version of SmartMove as the initial inspiration of the user interface for my C#/WinForms implementation, however the screenshots of the RISC OS version in the user manual looked rather more visually appealing and an archived copy of this software was available. Unfortunately, I don't own an Acorn Archimedes, I was unable to get the software running properly on modern RISC OS on a Raspberry Pi (even with various compatibility shims in place) and I couldn't find an emulator that handled the serial port in a similar fashion to DOSBox-X. However, the excellent Arculator has source code available and armed with a copy of the 6651 UART datasheet I thought I'd have a go at hacking in the feature myself.

"Hack" is definitely the operative word and though my code is abominable it does work well enough to get the available RISC OS software working on my PC. It's downloadable from here and requires the addition of the host PC's serial port name to arc.cfg (e.g. serial_port = COM1).